- English

- 简体中文

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

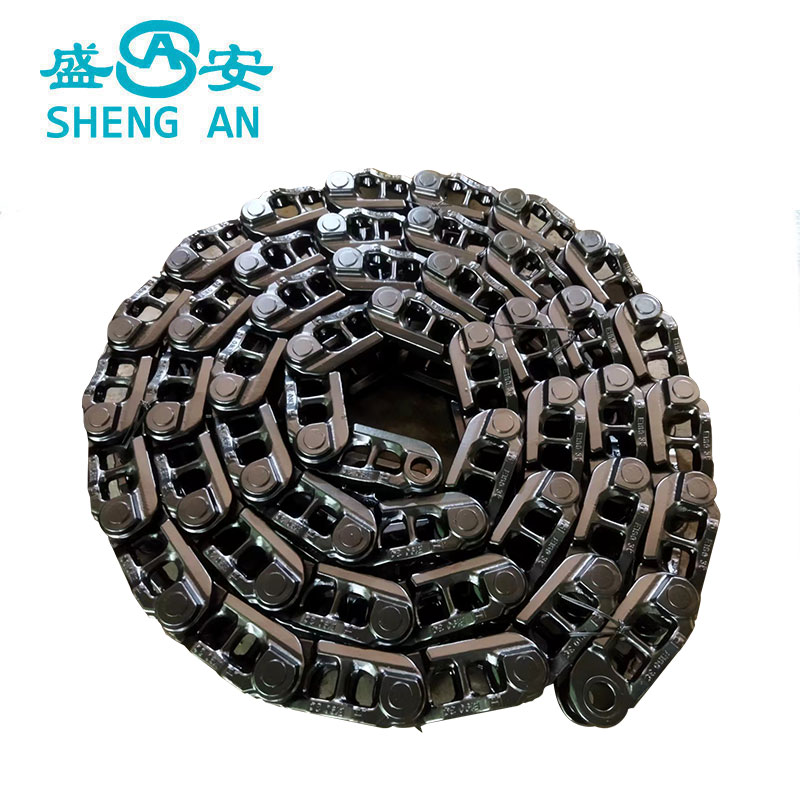

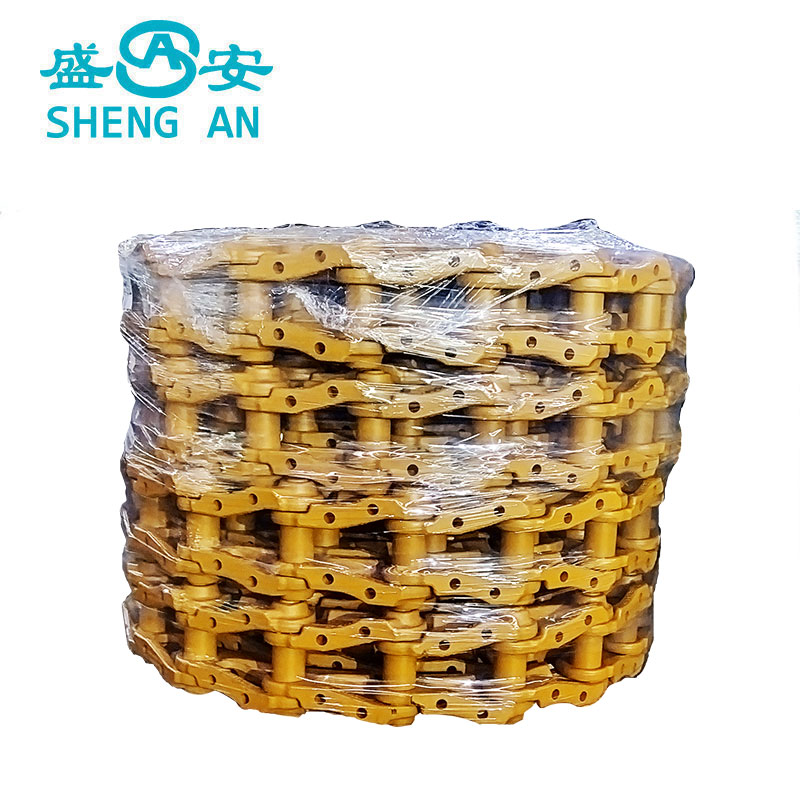

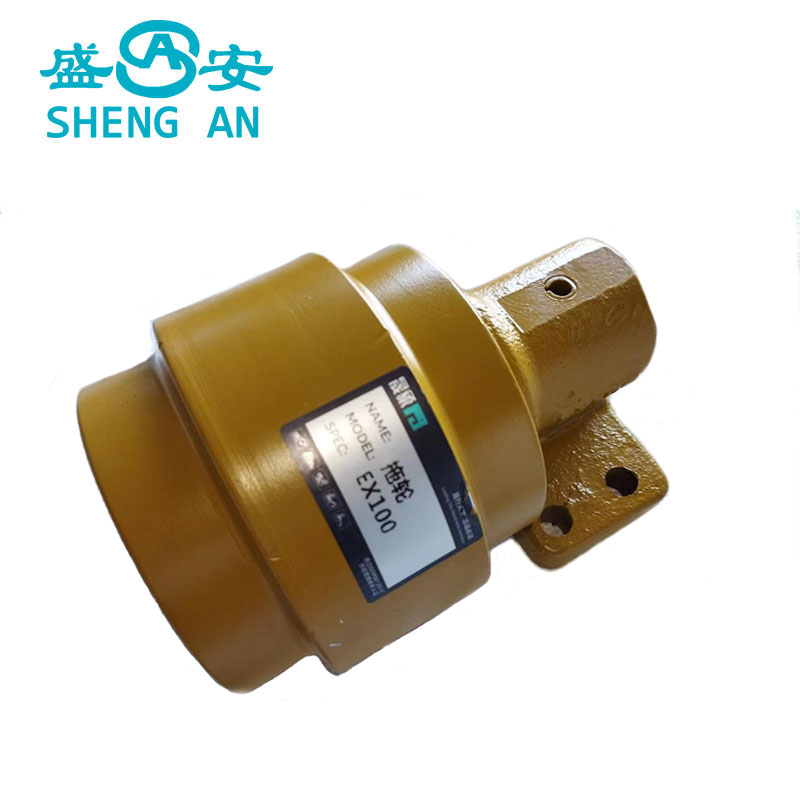

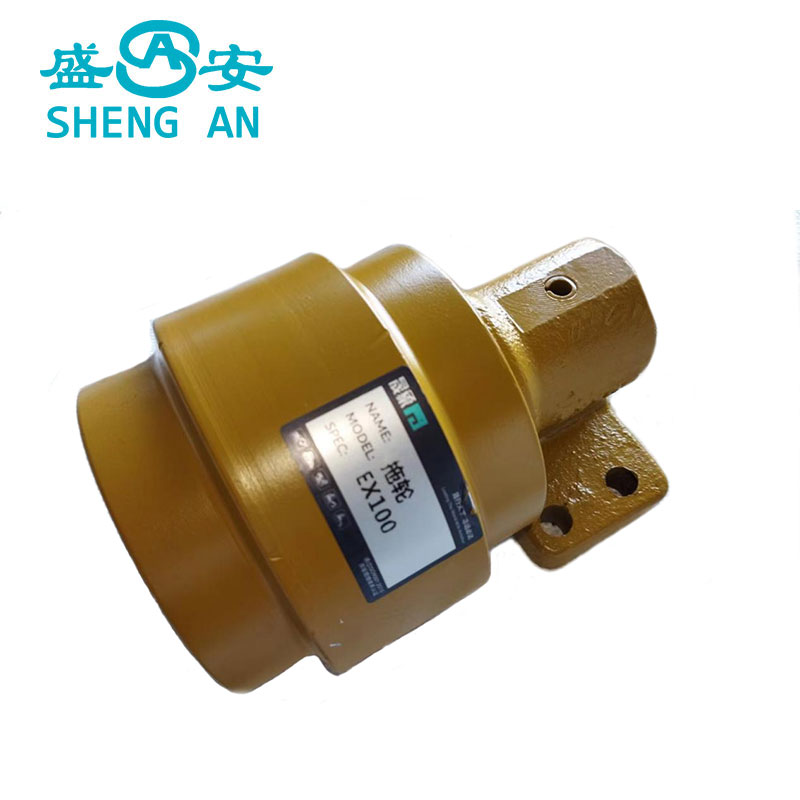

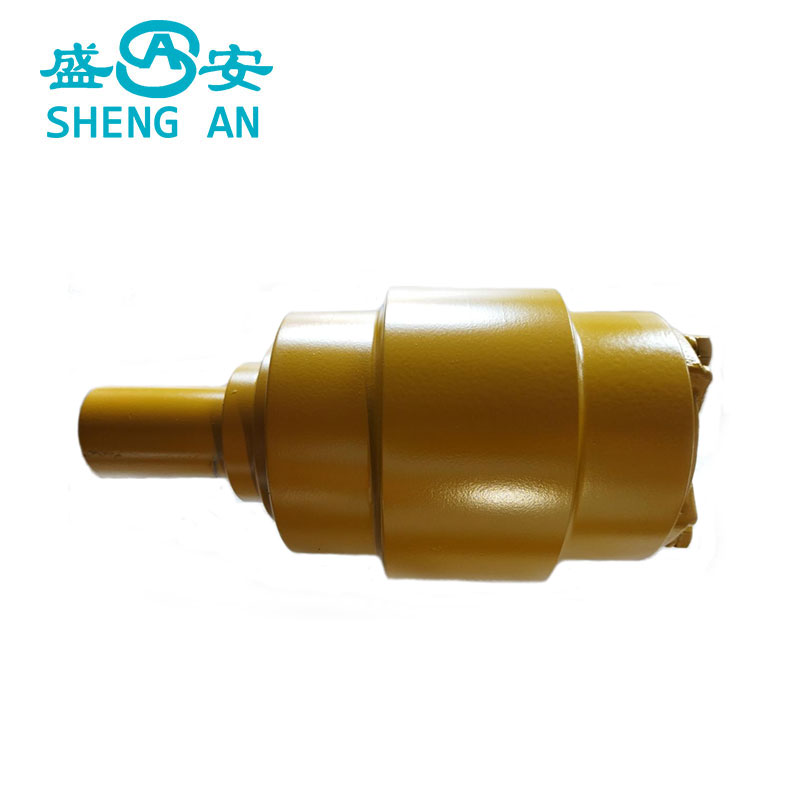

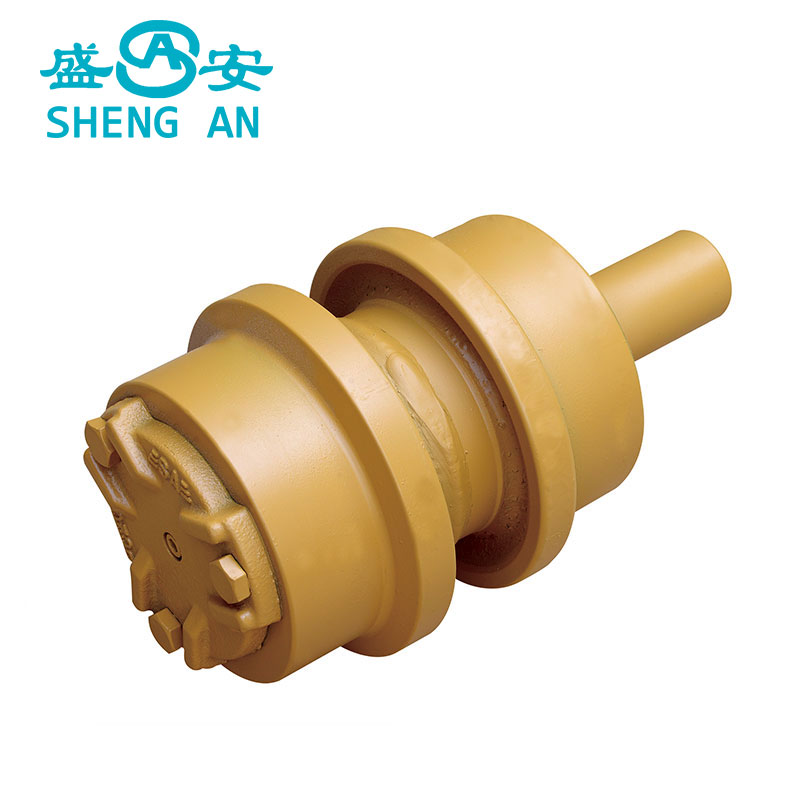

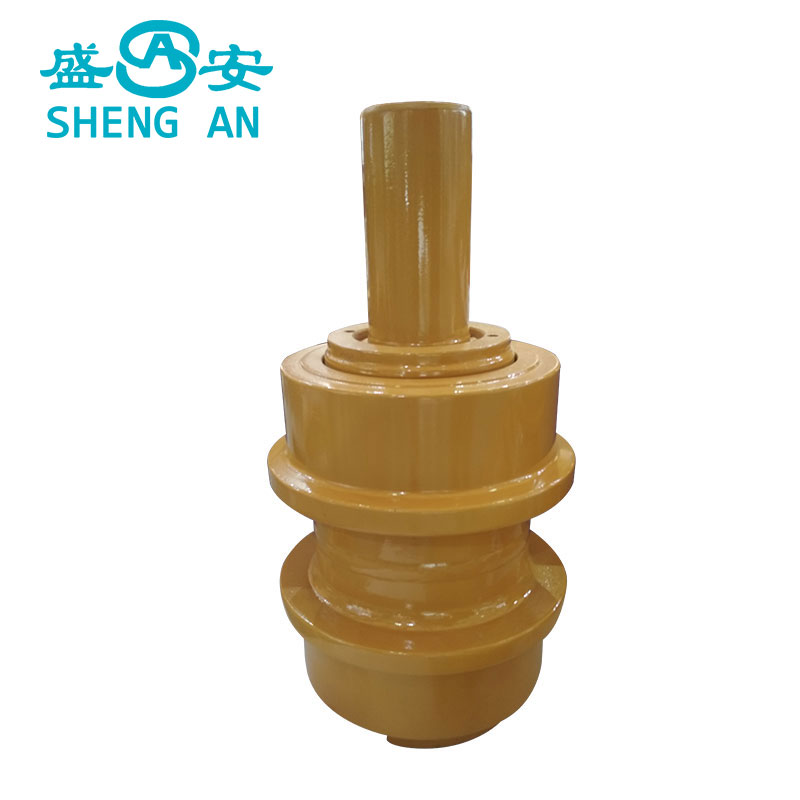

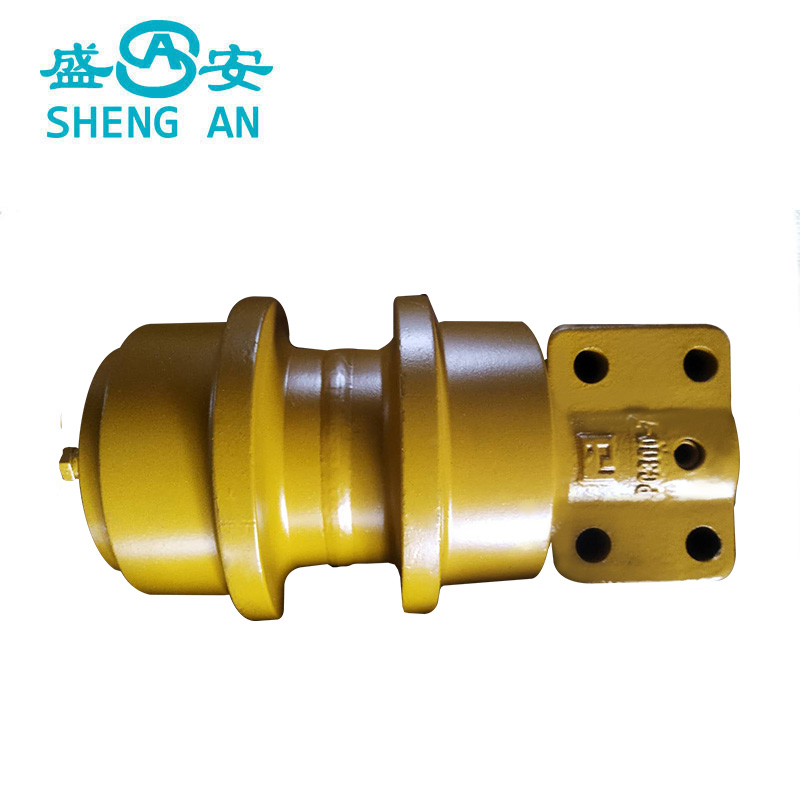

Carrier Roller

Fujian Sheng'an Machinery Development Co., Ltd., founded in 1985 and located in Quanzhou,Fujian, the starting point of the Maritime Silk Road, is a professional comprehensive enterprise integrating casting, forging, processing and assembly. It has been successively rated as a star enterprise and a major foreign exchange earner, and has obtained ISO9001 and ISO14001 international certifications. The main products we produce include: front idler, sprocket, segment, track roller, carrier roller, track link, bucket, swamp track shoe and other engineering machinery components for various models of excavators and bulldozers.Our company will strive for excellence, continuously improve the quality control system, improve the level of after-sales service, strive for progress, and work together with you to create brilliance.

Send Inquiry

The materials for the carrier roller shell are generally 40Mn2 or50Mn. The main process is forging, mechanical processing, and then heat treatment. The hardness of the wheel surface after quenching should reach HRC52-58 to increase the wear resistance of the wheel surface. The material of the carrier roller shaft is mostly 45# round steel, and the machining accuracy requirements are relatively high. Generally, CNC machine tools are required to process it to meet the requirements. After processing, quenching treatment is also required, and the hardness reaches around HRC52-56.

The function of the carrier roller is to support the track, prevent excessive sagging of the track, and provide a certain degree of tension on the track to reduce the vibration phenomenon of the track during movement. Simultaneously guide the direction of movement of the upper track and prevent the track from sliding sideways.

Product Parameter (Specification)

The carrier roller are strictly produced in accordance with production requirements. The material selection and assembly of the carrier roller comply with the drawings, and every parameter and indicator of the product is rigorously measured and tested.The following is the product specification table for the carrier roller:

|

Product name |

Carrier roller |

|

Roller shell material |

|

|

Color |

Black or yellow |

|

Surface of hardness |

|

|

Shaft material |

45#/40Cr |

|

Warranty period |

One year |

|

Case depth |

|

|

Delivery period |

30day/45-60day(negotiable) |

|

Using time |

1000hour |

Product features: Stable structure,shaft and bushing bronze is standard thickness and length. The copper layer is not easily peeled off after rolling, reaching over 3.5mm. Using high-quality bimetallic bushing bronze. Reliable sealing, wear-resistant roller shell, and low rolling resistance.

Roller shell: forging, rough turning, drilling oil holes, heat treatment, precision machining,, drilling collar installation holes, protective welding, and warehousing;

Shaft: cutting, rough turning, drilling oil holes, heat treatment, precision grinding, and warehousing;Assembly process: cleaning and polishing, assembly, pressure testing, refueling, painting, packaging and warehousing.

Each process undergoes strict inspection, with independent processing workshops and precision instruments, including specialized magnetic particle inspection machines to ensure that there are no cracks in the roller shell and the overall quality of the carrier roller.

Part number

The carrier rollers are divided into different specifications and sizes, and are used in different models of tracked construction machinery chassis.|

CATALOGUE |

||||||

|

PC20 |

PC30 |

PC40 |

PC55 |

PC60-1 |

PC60-5 |

PC60-6 |

|

PC71 |

PC100-5 |

PC120-5 |

PC200-5 |

PC220 |

PC300-5 |

PC400-5 |

|

DH50 |

DH55 |

DH80 |

DH130 |

DH220 |

DH250 |

DH258 |

|

DH300 |

DH500 |

DX30 |

DX35 |

DX55-9 |

DX60 |

DX80 |

|

E305-5 |

E305 |

E307 |

E35B |

E45 |

E50B |

E70B |

|

E300 |

E110 |

E120B |

E135 |

E140 |

E311 |

E312 |

|

EX30 |

EX50 |

EX55 |

EX60 |

EX60-2 |

EX70 |

EX70DF |

|

EX100 |

EX120 |

EX100M |

EX150 |

EX200-1 |

EX200-2 |

EX200-5/6 |

|

HD140 |

HD250 |

HD400-1 |

HD420-2 |

HD450 |

HD550 |

HD700 |

|

HD820 |

HD1250-5/7 |

HD2045 |

HD820 |

HD1250-5/7 |

ZN75 |

ZN160 |

|

R35 |

R50 |

R55 |

R60-5 |

R60-7 |

R80-7 |

R130 |

|

R210 |

R220-9 |

R260 |

R290 |

R305 |

R320 |

R335 |

|

SK04 |

SK042 |

SK045 |

SK30 |

SK35 |

SK35SR |

SK40 |

|

SK50 |

SK55 |

SK60 |

SK60-5 |

SK100 |

SK120 |

SK140 |

|

EC55 |

EC210 |

EC290 |

EC360 |

PH7035 |

PH7045 |

DRISOR |

|

YC85 |

SH60 |

SH120 |

SH200 |

ZBC60 |

NF130 |

BF200 |

|

SW50 |

SW70 |

R914 |

KX50 |

JD350 |

JD450 |

83765 |

|

D20 |

D30 |

D50 |

D65 |

D65EX-12 |

D85 |

D155 |

|

D355 |

D51EX |

D61EX |

D155 |

CX55 |

CX75 |

JS14 |

|

D3C |

D4D |

D5 |

D6D |

D7G |

D10N |

D11N |

|

洋马35 |

洋马55 |

洋马75 |

U15 |

U35 |

U60 |

U15 |

|

KX91-3 |

VIO17 |

HCR1500 |

TMX20 |

GM80 |

厦工806 |

191936 |

|

Z001S004 |

DH508 |

DSR200 |

SC650 |

U30-2 |

HDQ306 |

HQ307 |

Inventory

We have sufficient inventory, and the products you need can be prepared for shipment as quickly as possible.