- English

- 简体中文

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

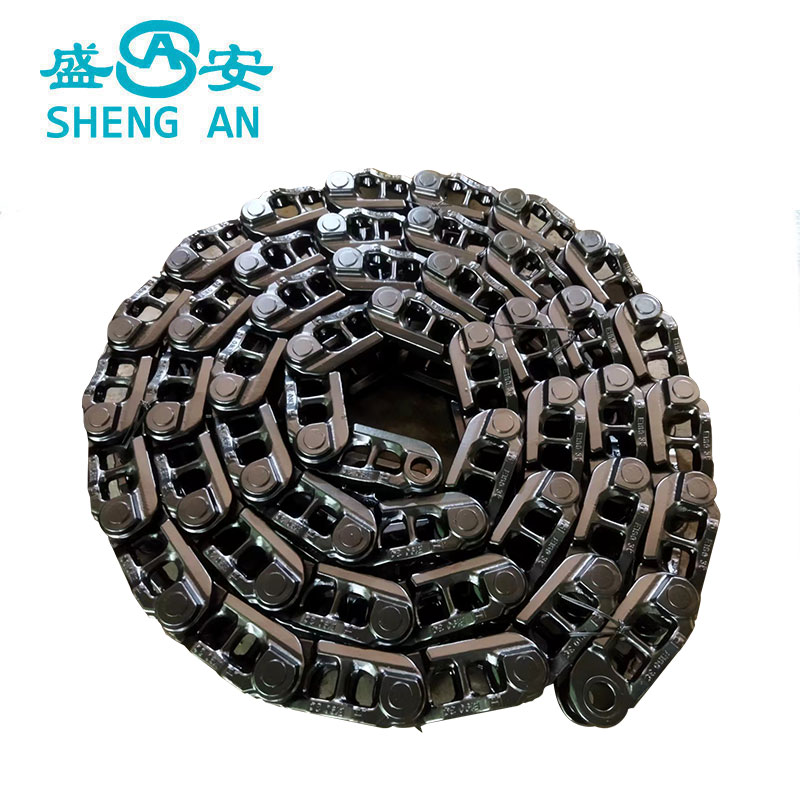

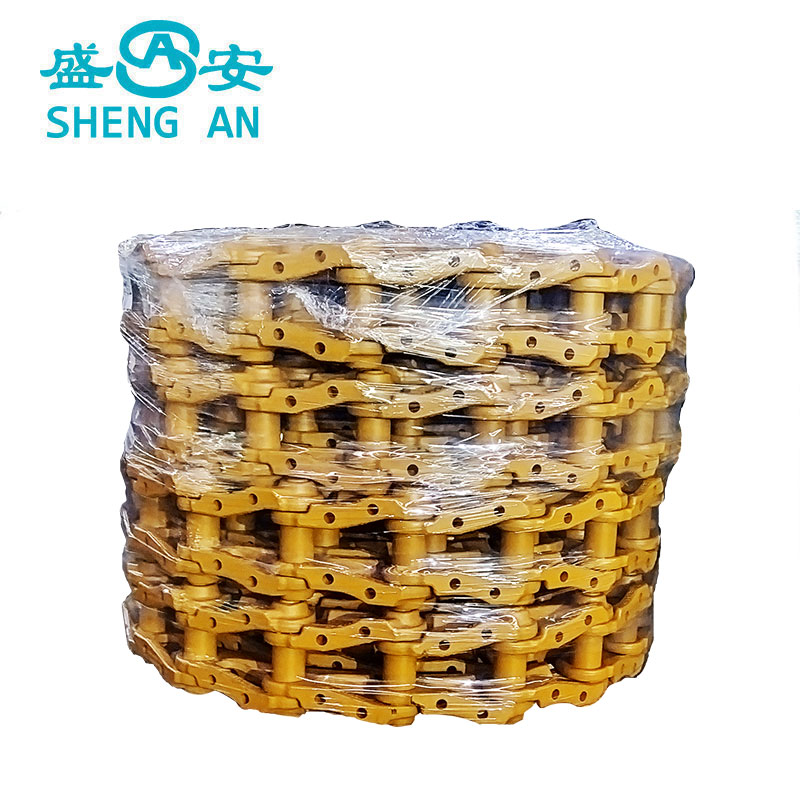

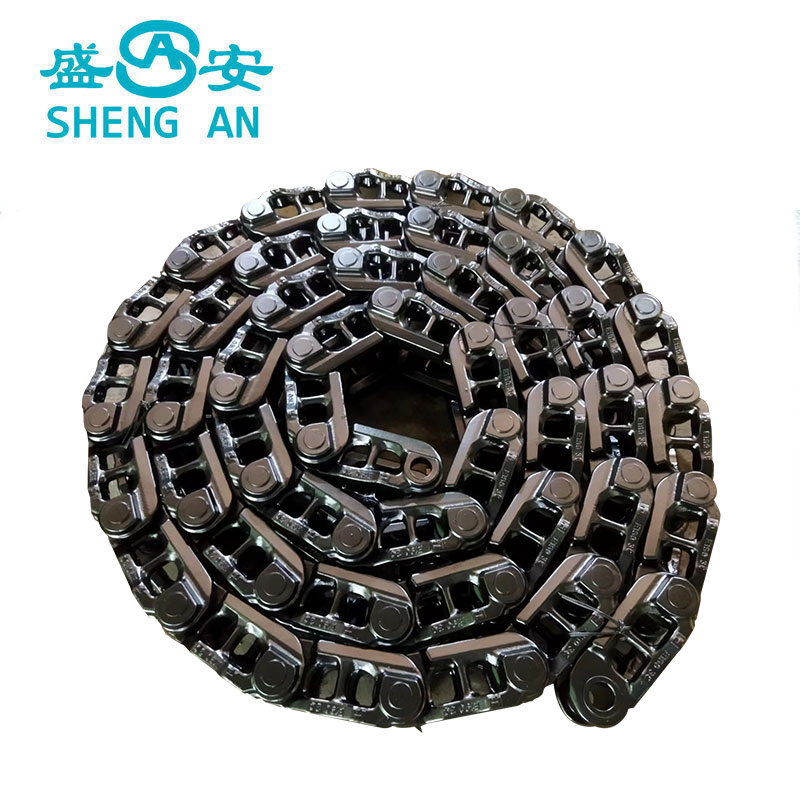

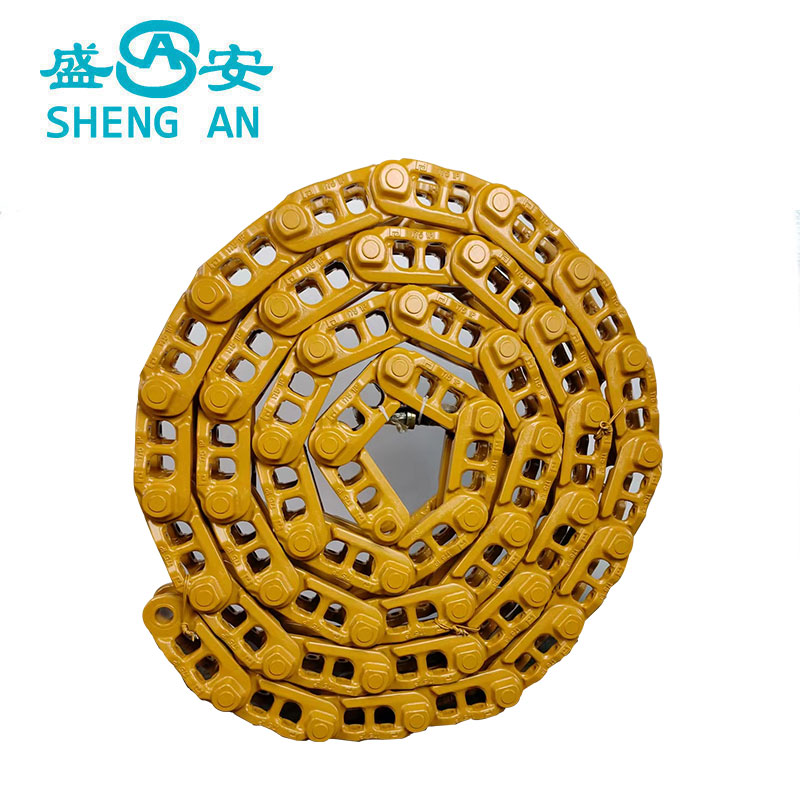

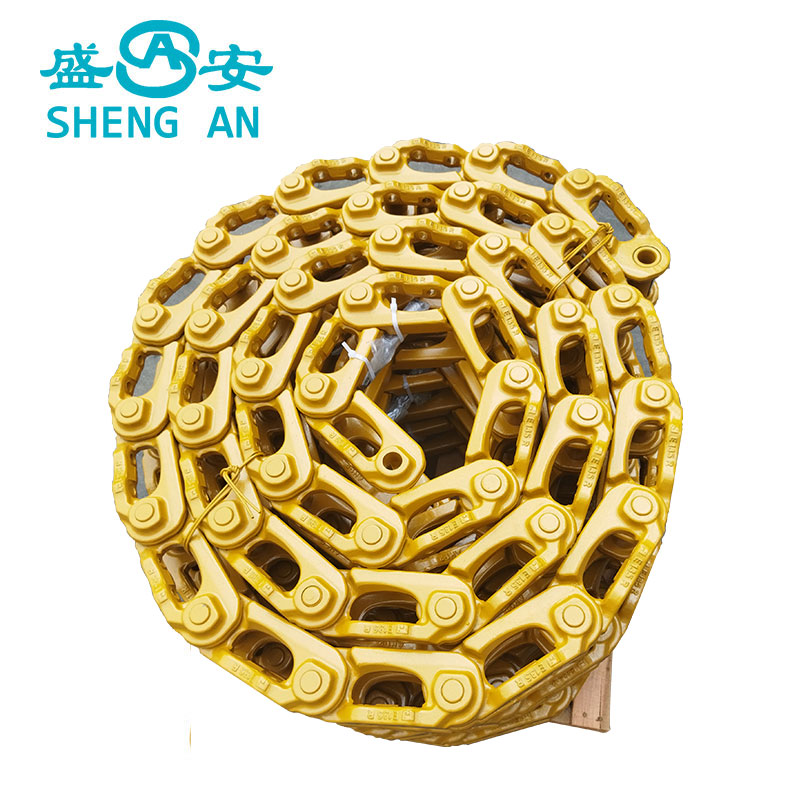

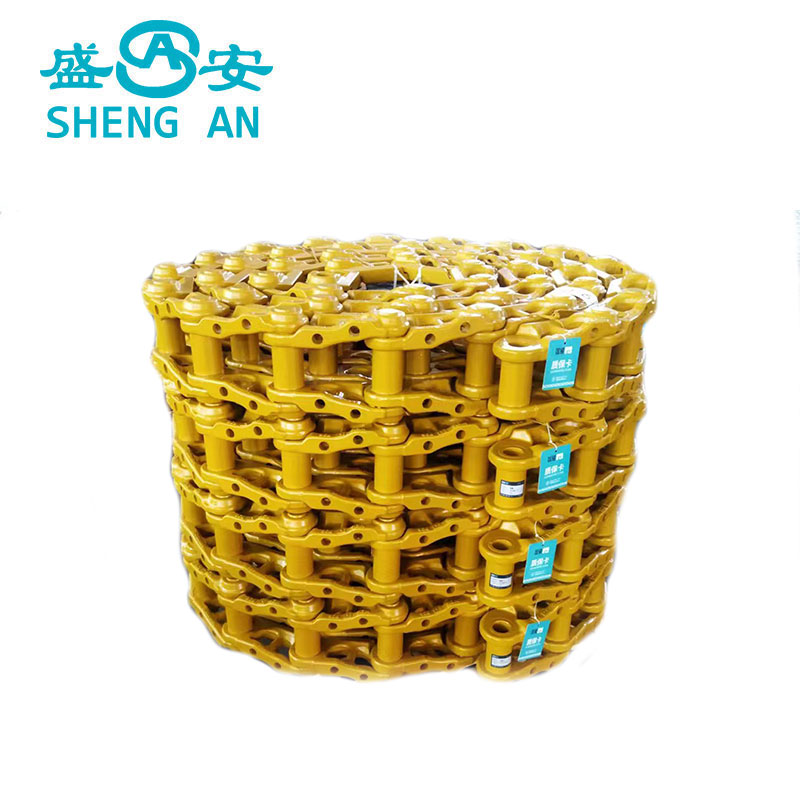

Excavator Track Chain Assembly

Fujian Sheng'an Mechinery Development Co., Ltd. is a professional enterprise engaged in the research and development, manufacturing, sales, and service of chassis parts for construction machinery. The company is located in Daxiamei Industrial Zone, Nan'an District, Quanzhou City. Sheng'an Machinery mainly produces various specifications and models of excavator, bulldozer chassis components and other mechanical products,Excavator Track Chain Assembly。 Shengan Machinery has always been renowned for its excellent quality and service both domestically and internationally. The company's products perform excellently in terms of quality, cost-effectiveness, and pre-sales and after-sales service. Its mechanical products are widely sold in domestic and foreign markets and are highly praised by users. At the same time, we are still continuously introducing advanced domestic and foreign technologies, innovating design and production processes, and providing sufficient power for product upgrades and upgrades. Sheng'an Machinery adheres to the business philosophy of customer-centered, technology-led, quality-based, and service-oriented. It continuously promotes sustainable development strategies, provides customers with high-quality products and honest services, and makes positive contributions to the development of China's construction machinery industry.

Send Inquiry

The excavator track chain assy is one of the important components of the excavator track system, usually composed of chain pieces, chain plates, chain pins, bolts, shaft sleeves, and washers. The design of excavator track chain assy can be adjusted based on different working environments and operational requirements to achieve better durability, load-bearing capacity, and transmission efficiency.

The main function of the excavator chain assy is to transfer power from the excavator engine to the track system, thereby driving the excavator to travel and work. The excavator track is also an important working part. In the operation of excavators, the track system needs to withstand considerable impact and pressure, so the excavator chain needs to have very high durability, wear resistance, and strength.

Excavator track chain assy are usually classified according to different models and brands of excavators, and can be divided into different models such as standard chains, heavy-duty chains, high-strength chains, etc. Different models of chains have different load-bearing capacity, wear resistance, transmission efficiency, and service life, and should be selected according to specific work scenarios and operational requirements. Meanwhile, during the use of excavator chains, regular inspections and maintenance should be carried out to avoid work interruptions and safety accidents caused by chain damage.

Excavator Track Chain Assembly Product Parameter (Specification)

The following are the specifications and parameters of the excavator track chain assy:

|

Product name |

Excavator track chain assy |

|

Material |

35MnBH |

|

Color |

Black or yellow |

|

Surface of hardness |

|

|

Warranty |

Crack |

|

Case depth |

|

|

Delivery period |

45-60day |

|

Using time |

2000hours |

The excavator track chain assy has the following characteristics:

High strength: The excavator track chain assy needs to withstand a large amount of pressure and impact, so it needs to have high strength and hardness to ensure its long-lasting and durable performance.

Strong wear resistance: Excavator track chain assy are usually in high friction and high load working environments, requiring strong wear resistance to withstand long-term friction and wear, thereby improving service life and reducing maintenance costs.

Strong load-bearing capacity: The load-bearing capacity of the excavator chain determines the load-bearing capacity and work efficiency of the excavator. Therefore, when designing and manufacturing the chain, it is necessary to fully consider its load-bearing capacity and support for the track.

Stable and reliable quality: The excavator track chain assy needs to withstand complex environmental impacts such as bumps and vibrations during excavator operation. Therefore, stable and reliable quality is required in design and manufacturing to ensure efficiency, safety, and durability during the working process.

Wide adaptability: The excavator track chain assy can be customized according to different models and uses. Meanwhile, excavator chains can be widely used in various construction and engineering applications.

In summary, the high strength, wear resistance, load-bearing capacity, stable and reliable quality, and wide adaptability of excavator chains ensure the driving, steering, and operation of excavators, fully reflecting their indispensable role in excavator track systems.

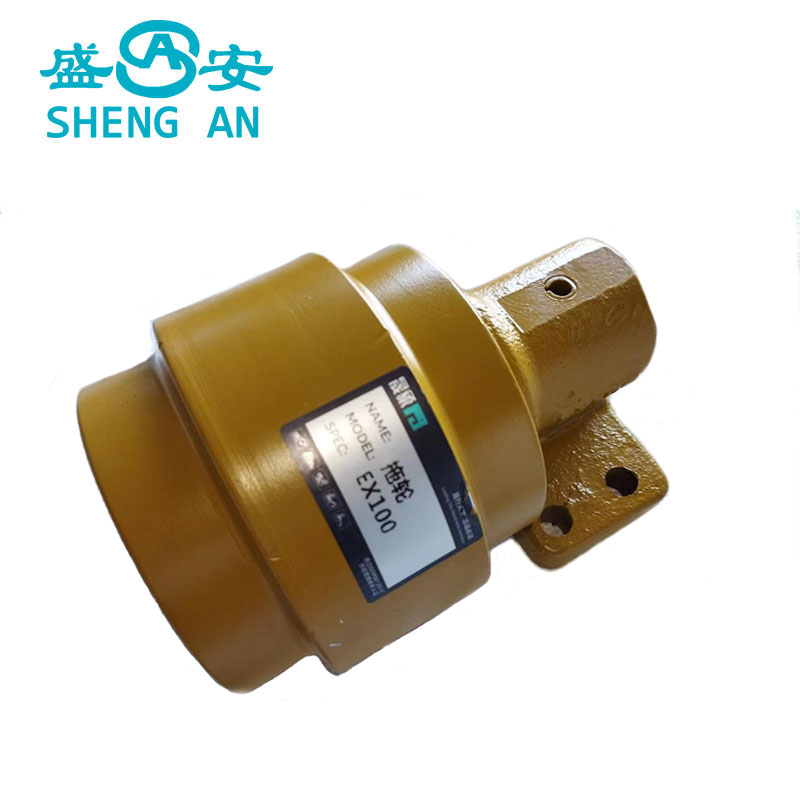

Excavator Track Chain Assembly Part number

We have produce the following models.

|

PC45-1 |

EX100 |

DH150 |

E320 |

BD2G |

YC85 |

|

PC40-7 |

EX200-2 |

DH220-3 |

E325 |

D20 |

YC135 |

|

PC56 |

EX300-2 |

DH220-5 |

E70B |

D57 |

SWE55 |

|

PC60-3 |

EX60 |

DH258 |

E110B |

D4D |

山推SD16 TY160 |

|

PC60-6 |

EX200-1 |

DH280 |

E311 |

D31 |

SD16TL TSY16L |

|

PC60-7 |

EX400-2 |

DH280LC |

E120 |

D60P-12 |

LS2600 |

|

PC75 |

EX55 |

DH320 |

E200B |

SK100 |

柳工906 |

|

PC100-3 |

EX40 |

DH320LC |

E140 |

SK60-3 |

徐工75 |

|

PC100-5 |

EX45 |

DH50 |

E320 |

SK220-5 |

K904B |

|

PC120-5 |

EX100-1/2/3/5 |

DH55 |

CAT315 |

SK230-6 |

PC300-6 |

|

PC120-6 |

EX130 |

R130 |

CAT325 |

SK250 |

PC300LC-3 |

|

PC130-6 |

EX150 |

R180LC-3 |

E330 |

SK200-6 |

PC400-5 |

|

PC200-1/2/3 |

EX210LC-5 |

R210-3 |

E240B/C |

SK200-3/5 |

PC400-6 |

|

PC200-5 |

EX200LC-2/3/5 |

R260 |

E120B |

HD55-5 |

PC230LC-6 |

|

PC200-6 |

EX300-2 |

R290LC |

E312B |

HD450 |

PC300-3 |

|

PC200-5 |

EX120-1 |

R320 |

E110 |

HD1023 |

PC300-5 |

|

PC200-3 |

EX300LC-1/2/3 |

R55 |

ZX870 |

HD550 |

EX230-5 |

|

PC210LC-2/5/6 |

EX300-1/2/3 |

R60 |

ZAX120 |

HD1250 |

EX220-2/3/5 |

|

PC200LC-2/3 |

EX120-2/3/5 |

SH60 |

ZX330-3 |

HD1430 |

EX240 |

|

PC220-3 |

EX210-5 |

SH300 |

ZAX234 |

HD820 |

SH260 |

|

PC220LC-2/3 |

EX200-2/3/5L |

SH200 |

ZAX240 |

HD823 |

SH265 |

|

PC220-5/6 |

EX100M-5 |

SH100 |

ZX200 |

EC210LC-3 |

SH220 |

|

PC220LC-3/5/6 |

EX220-1/2/3/5 |

SH120 |

ZX210 |

EC140 |

|

|

PC230-6 |

EX70 |

SH460 |

ZX200LC |

EC240 |

|

Excavator Track Chain Assembly Inventory

We have a lot of inventory,if your order is very urgent,we can quickly stock up.