- English

- 简体中文

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

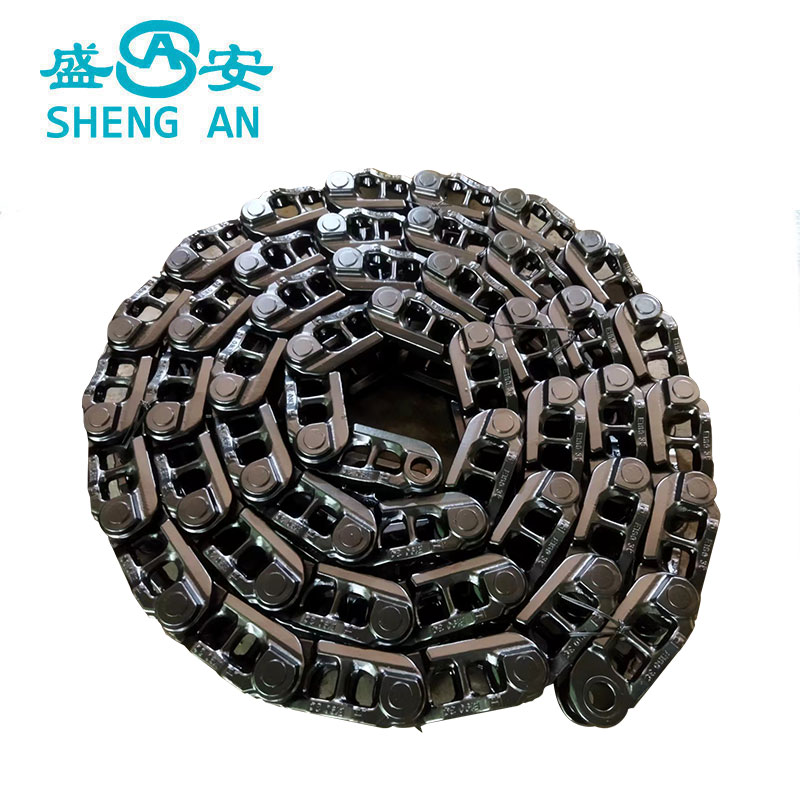

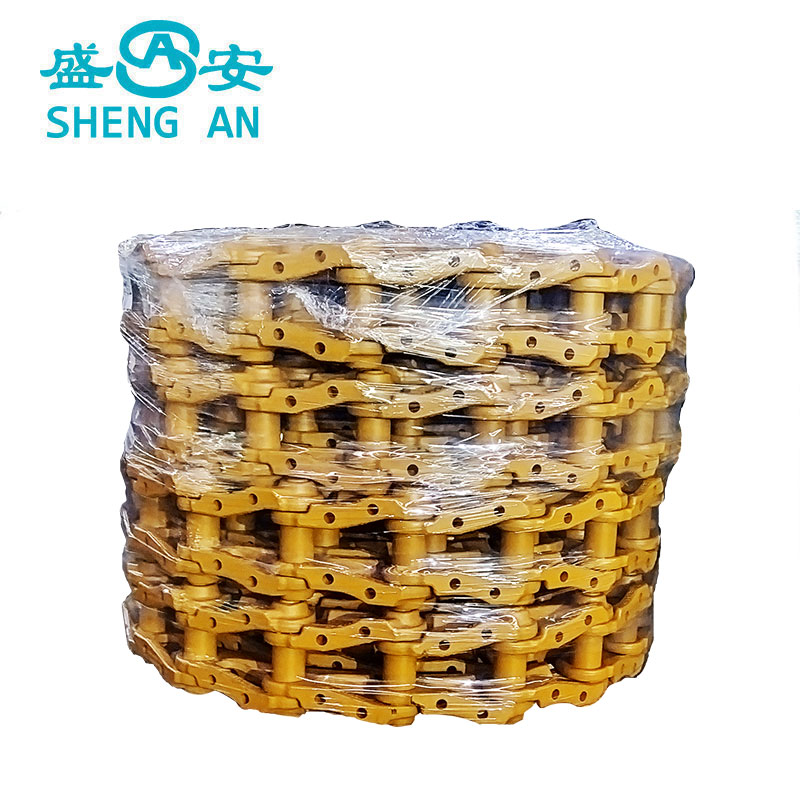

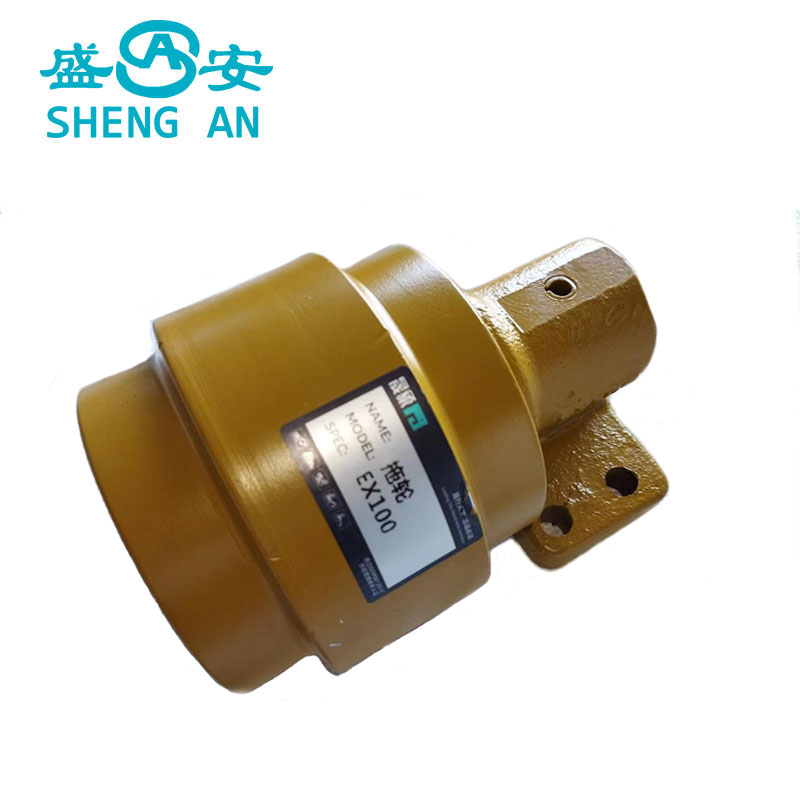

Front Idler Group

Fujian Shengan Machinery Development Co., Ltd. was founded in 1998.The company is a professional manufacturer of engineering machinery, focused on research and development, production, sales, and services. The company's main front idler group include excavators, bulldozers and many other engineering machinery products, as well as a variety of parts and services. Shengan Machinery is committed to continuous improvement of its technology and production capabilities through innovation. The company has obtained numerous honors and patents, and has obtained ISO9001 Quality Management System Certification and CE Certification, and has won various honors and certificates for its products.

Send Inquiry

The company adheres to the enterprise spirit of "people-oriented, innovation-driven, honesty, and excellence", pursues continuous improvement of technology and quality, and always puts customer needs first. The company insists on putting quality first and the customer first,vigorously develops domestic and foreign market.Excavator front idler are an important component of an excavator, specially designed to support the excavator's tracks and propulsion system.

Here are some key features of excavator front idler:

Materials: Excavator front idler are typically made of high-strength alloy steel or cast iron, providing durability and resistance against different types of working environments.

Structural form: Excavator front idler have a similar structure to idler wheels, including a central shaft, inner and outer shells, and a horseshoe plate.

Function: The guide wheel is located at the front of the excavator's tracks, mainly used to maintain the stability of the tracks and reduce the lateral sliding of the tracks, ensuring the excavator's stability in different working environments.

Adjustment: The excavator front idler have some adjustable functions. According to the different models and working conditions of excavators, the height and angle of the wheels can be adjusted to suit various working environments.

In summary, excavator front idler are an important component for excavator machinery, ensuring stable and smooth movement of tracks. Therefore, their design and manufacture must consider various environmental factors to ensure the stable operation and movement of excavator tracks.

front idler group Parameter (Specification)

|

Product name |

IDLER |

|

Material |

|

|

Color |

Black or Yellow |

|

Surface hardness |

|

|

5-10mm |

|

|

Warranty |

one year |

|

Production Process |

Forging |

Part number

The company's products are of superior quality and excellent performance, and they sell well in both domestic and foreign markets, winning the praise of customers.|

CATALOGUE |

|||||||

|

PC20 |

EX30 |

SK30 |

R60 |

DH55 |

EC55 |

JS140 |

徐工60 |

|

PC30 |

EX55 |

SK35SR |

R80 |

DH80 |

EC60 |

JS200 |

龙工60 |

|

PC30-7 |

EX40 |

SK55 |

R130 |

DH150 |

EC140 |

JS200-2 |

SY65 |

|

PC40-7 |

EX60-1 |

SK40 |

R150-7 |

DH220 |

EC210 |

MS110 |

KH035 |

|

PC50UU |

EX60-2 |

SK50 |

R200 |

DH258 |

EC240 |

MS120 |

KX91-3 |

|

PC56 |

EX70 |

SK042 |

R215-9 |

DH280 |

EC290 |

MS180 |

TB150 |

|

PC50N2 |

EX100-1 |

SK60 |

R225-7 |

DH300 |

EC290 |

MM30 |

IHI30 |

|

PC50N1 |

EX100-3 |

SK60-8 |

R210 |

DH360 |

EC360 |

MM35 |

SE280 |

|

PC55 |

EX100-5 |

SK100 |

R290 |

DH370 |

EC460 |

MM45 |

CX210 |

|

PC60 |

EX150-1 |

SK200 |

R305 |

DH420 |

YC35 |

VIO35 |

UH063 |

|

PC100-3 |

EX200 |

SK220 |

R305 |

DH500 |

YC60 |

VIO55 |

|

|

PC100-5 |

HD700 |

SK300 |

R912 |

E305.5 |

YC85 |

LS2800FJ |

|

|

PC200-3 |

HD820 |

SK330-3 |

SH60 |

E307 |

YC85 |

LS2600FJ |

|

|

PC200-5 |

EX300-1 |

SK330-8 |

SH120 |

E70B |

YC135 |

JBT60 |

|

|

PC200-5 |

EX300-2 |

SK07N2 |

SH125-3 |

E120B |

HD250 |

JBT50 |

|

|

PC200-7 |

EX300-3 |

SK045-5 |

SH120A3 |

E312 |

HD450 |

|

|

|

PC200-8 |

EX300-5 |

SK045-2 |

SH200 |

E200B |

HD1250 |

|

|

|

PC300-3 |

EX400 |

ZAX33 |

SH260FA |

E320 |

HD1430 |

|

|

|

PC300-5 |

DX55 |

ZAX80-3 |

SH350 |

E324 |

JCB220 |

|

|

|

PC300-6 |

DX60 |

ZAX330-8 |

SH300-5 |

E322 |

JCB290 |

|

|

|

PC400 |

DX220-9 |

ZAX200 |

SH340 |

E325 |

SWE85 |

|

|

|

PC800 |

DX300 |

ZAX330-5 |

SH240 |

E330 |

SWE70 |

|

|

Inventory

Sheng'an Machinery has a diverse product line and good inventory management, with sufficient inventory and a wide variety of products.