- English

- 简体中文

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

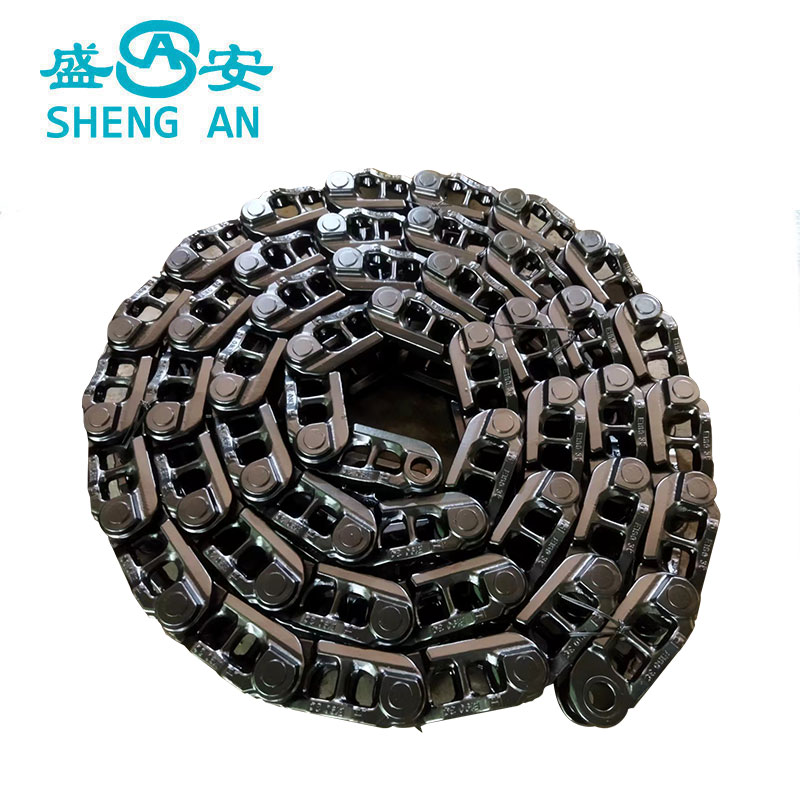

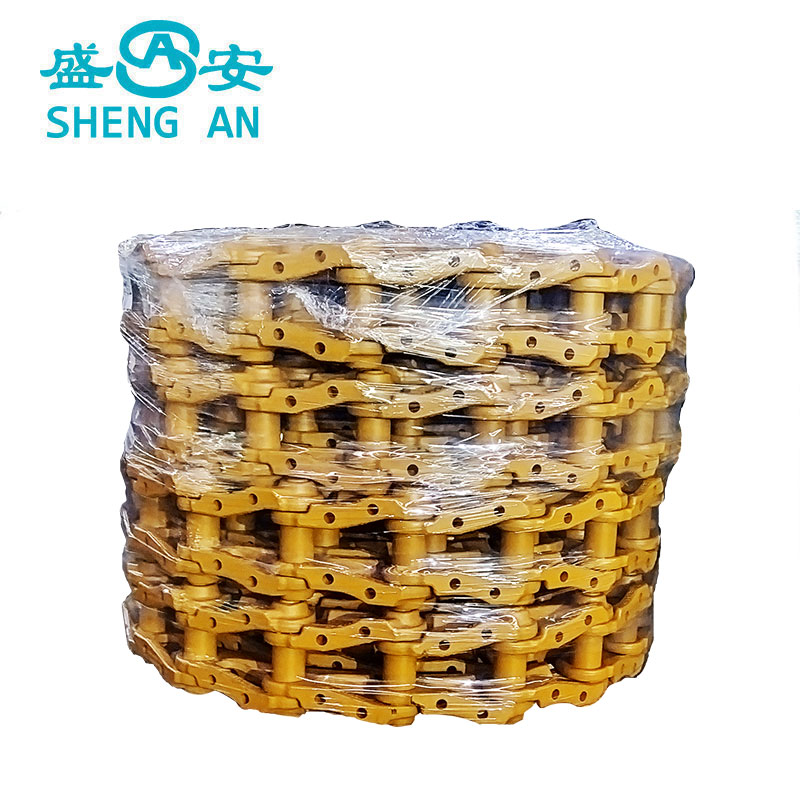

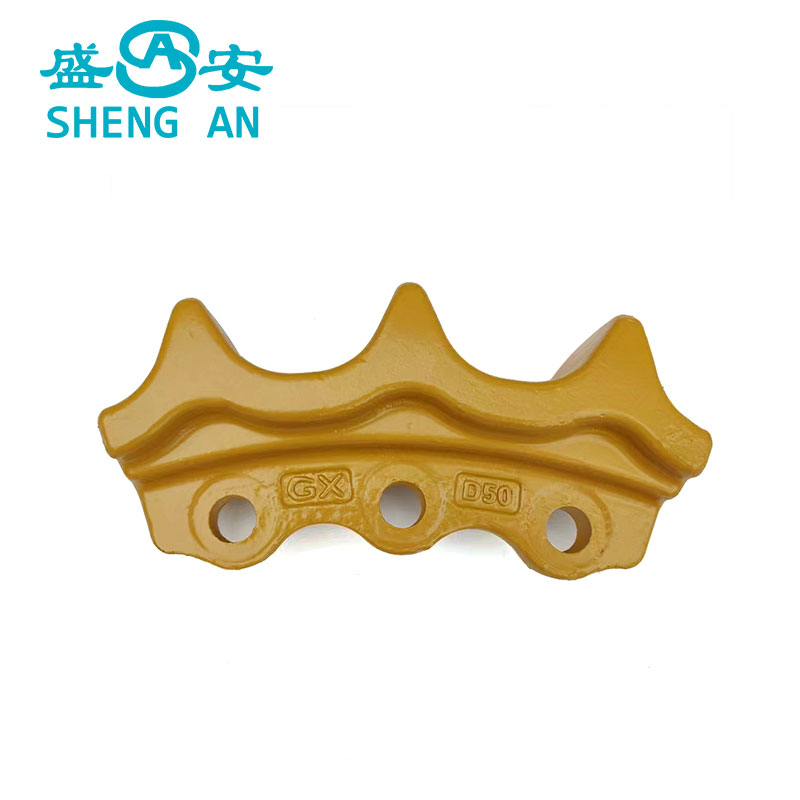

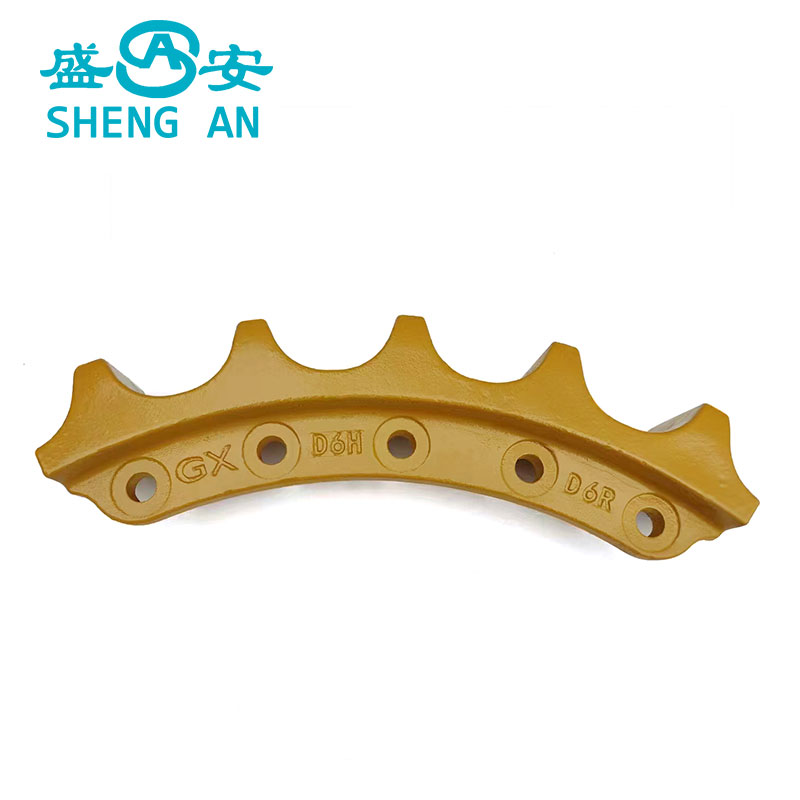

Dozer Sprocket Segment

Wholesale Dozer Sprocket Segment made in China from Shengan Mechinery, which is one of the manufacturers and suppliers in China. Buy latest selling Dozer Sprocket Segment with low price from our factory.

Send Inquiry PDF DownLoad

Shenganis a professional China Dozer Sprocket Segment Manufacturers and China suppliers. We stick to the principal of quality orientation and customer priority, we sincerely welcome your letters, calls and investigations for business cooperation.

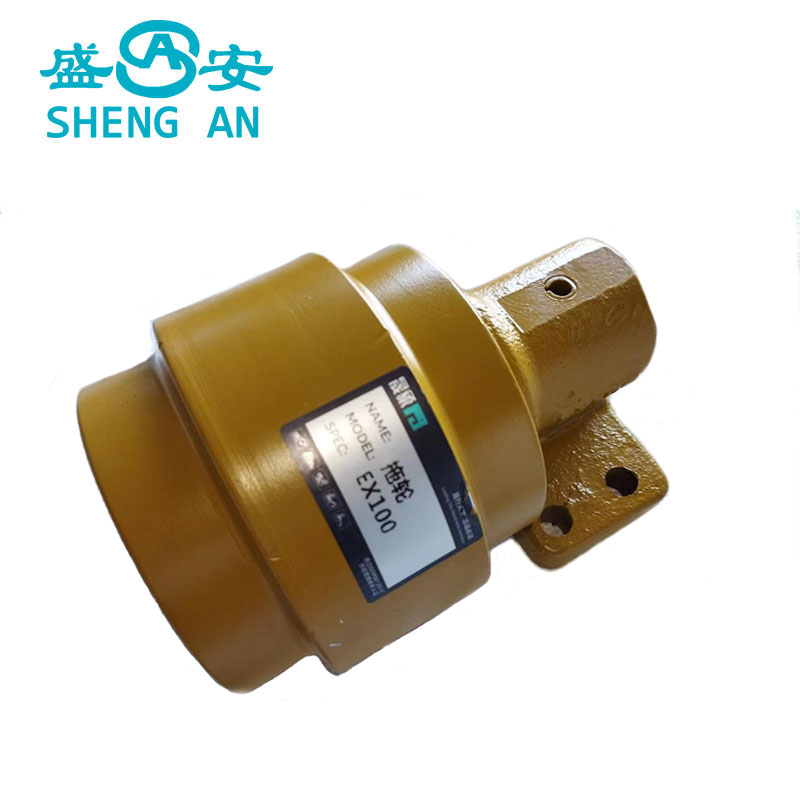

Fujiansheng Shengan Mechinery Development co.,Ltd is a large scale excavator parts manufacturer and supplier in China. It has been established over 35 years Dozer sprocket segment. We have professional heat treatment facilities to provide high quality products, short delivery time and the best service for our customers. Our factory mainly produces excavators, bulldozers parts. Track roller, carrier roller, sprocket, front idler, track chain, bucket, swamp track shoe and etc. Our products have been recognized and supported by customers in many countries. We often participate in exhibitions.

Choose us and we will bring you professional products and excellent service.

The excavator engine is transmitted to the crawler through the travel motor and the sprocket, which requires the sprocket and the track chain of the crawler to be properly meshed, the transmission is smooth, and the crawler can still mesh well when the track is stretched due to wear of the pin sleeve.

The excavator sprocket are usually located at the rear of the excavator travel gear.

Product Parameter (Specification)

|

Model Name |

Dozer sprocket segment |

|

brand |

SA |

|

Material |

50Mn |

|

Color |

Black or Yellow |

|

Surface Hardness |

HRC55-58 |

|

Application |

Crawler Excavator |

|

Warranty time |

1000 hour |

|

Technique |

Casting |

|

Usage |

Crawler track chain machine |

|

Application |

Excavator parts |

Product Details

Dozer sprocket segment

1.The excavator sprocket are usually located at the rear of the excavator travel gear.

2.According to the structure, it can be divided into: integral type, split type.

3.According to the pitch, it can be divided into: equal pitch, unequal pitch.

4.Material: 35MN2, and make its hardness reach HRC55-58.

Dozer sprocket segment

|

BRAND |

CATALOGUE |

|||||||

|

BULLDOZER |

D20 |

D20 WELDING |

D31-17/18 |

D31 WELDING |

D31-21 |

D41E-6 |

D50 |

|

|

SPROCKET |

D60 |

D50 WELDING |

D75 |

D85 |

D155 |

D4D |

D6D |

|

|

D6R |

D7G |

D8R |

|

|

|

|

||

|

SEGMENT |

D3C |

D3K |

D4H |

D5H |

D5G |

D5C |

D5B |

|

|

D5 |

D6H |

D6R |

D6C |

D6D |

D6M |

D7G |

||

|

D7R |

D8N |

D8R |

D9N |

D50A-17 |

D65 |

D65EX-12 |

||

|

D68EX |

D85A-18 |

D85A-21 |

D155AX-3 |

D275 |

D355 |

D6K |

||

Product process

Dozer sprocket segment