- English

- 简体中文

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

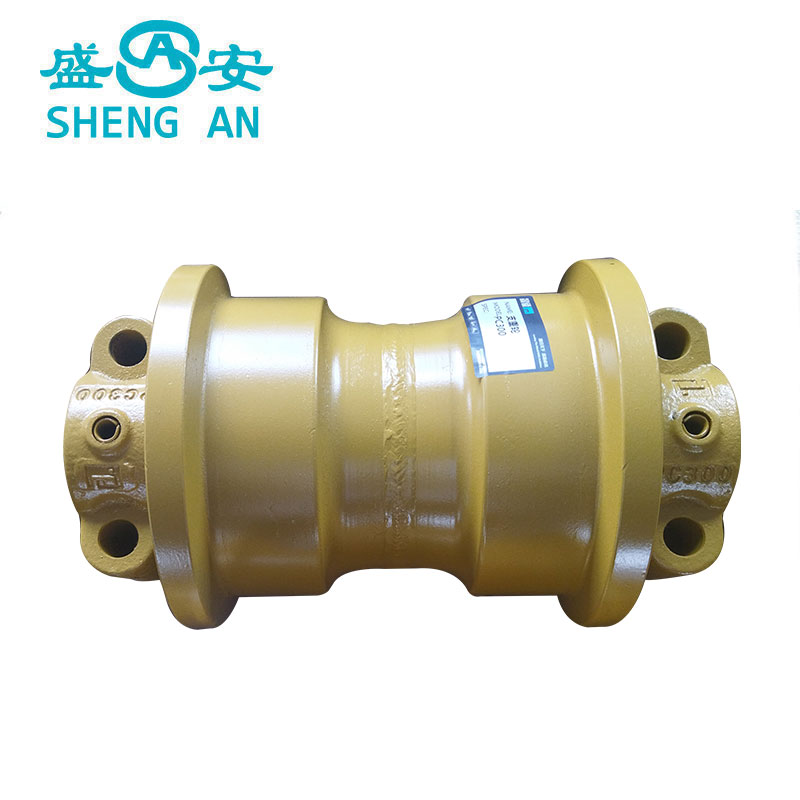

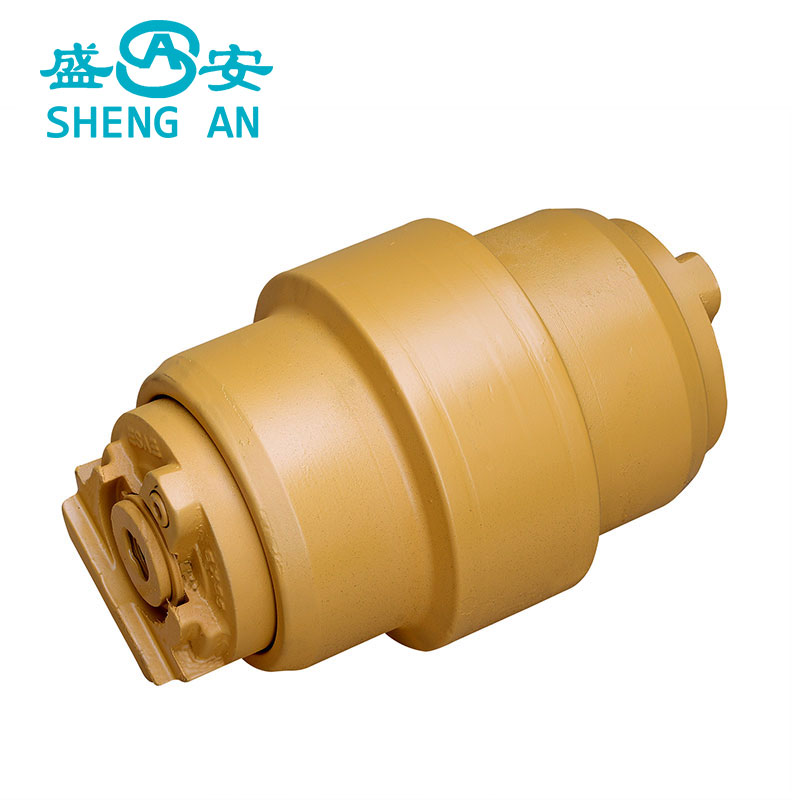

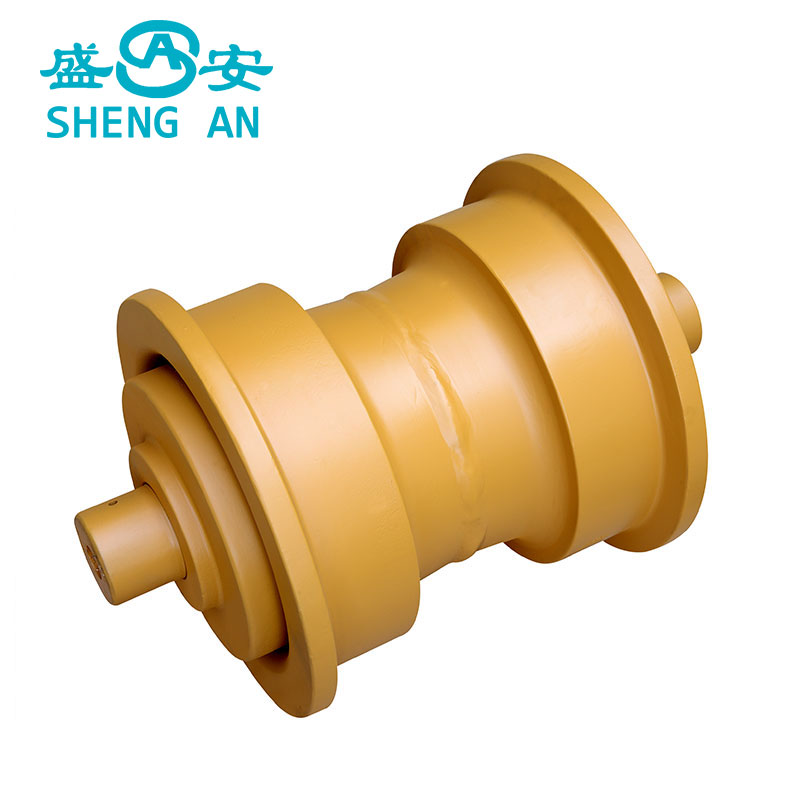

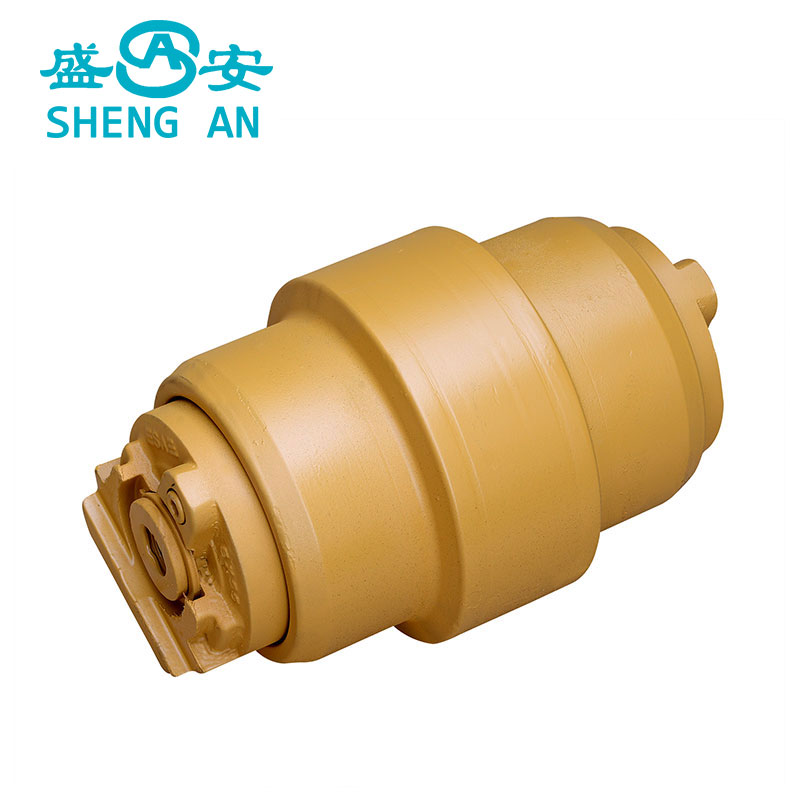

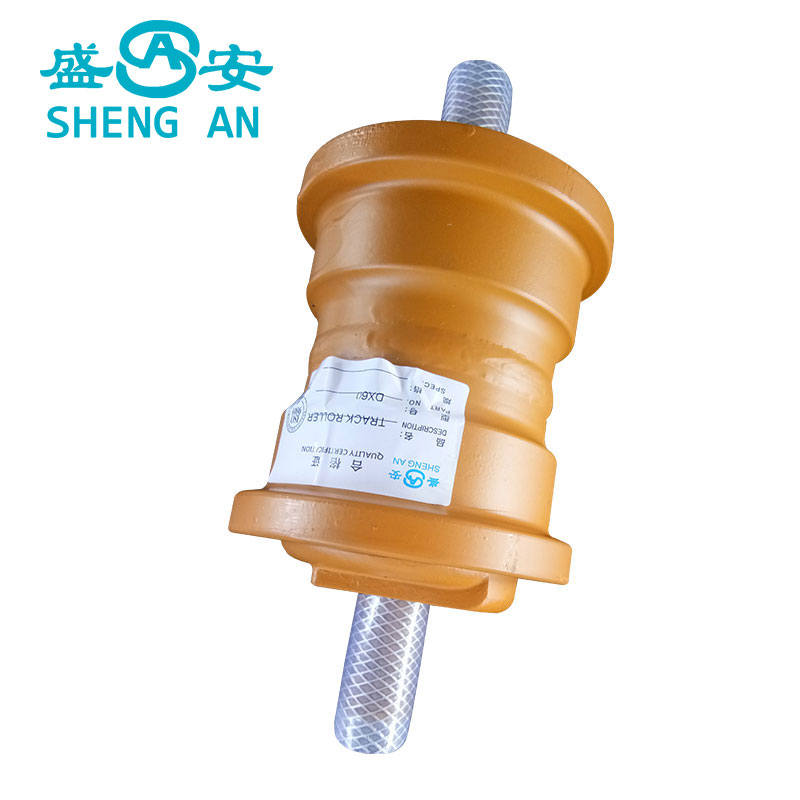

Excavator Bottom Roller

Fujian Sheng'an Machinery Development Co., Ltd. was established in 1985, with its headquarters located in Nan'an, Fujian. This is a company specializing in the research and development, production, and sales of excavators, Excavator Bottom Roller,bulldozers, and excavator components. The main products of Fujian Shenan Machinery include chassis accessories for excavators and bulldozers. The company's R&D and manufacturing capabilities have always been at the forefront of the industry, and its products are renowned in domestic and international markets. Fujian Shengan Machinery focuses on quality and service, with a comprehensive after-sales service team and extensive sales network. The company always adheres to the business philosophy of "market-oriented and customer-centric",aiming to provide customers with high-quality, high-performance, and cost-effective mechanical equipment, and striving to become a world-class excavator parts manufacturing enterprise.

Send Inquiry

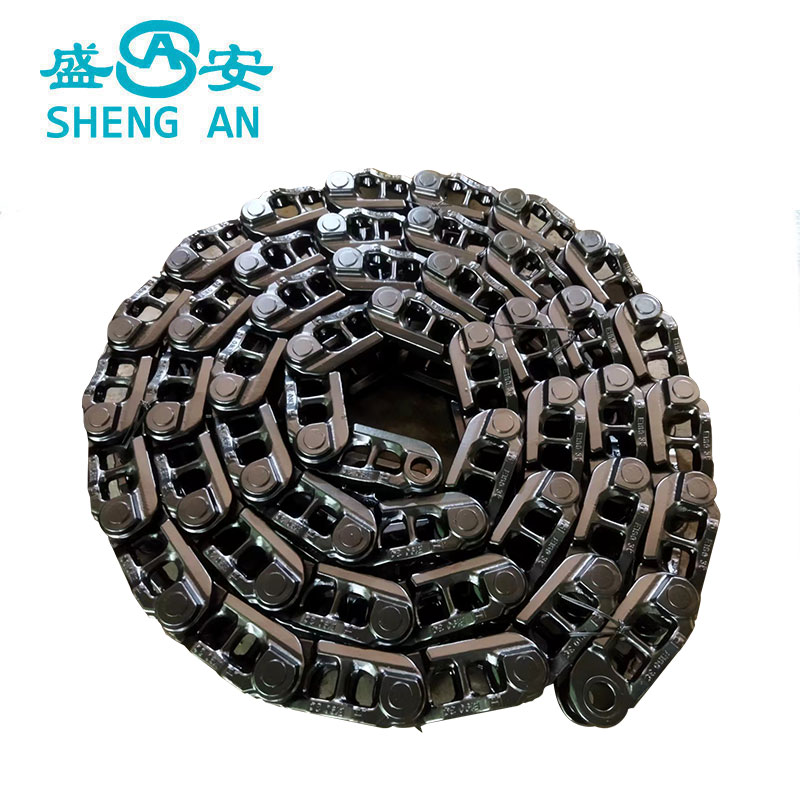

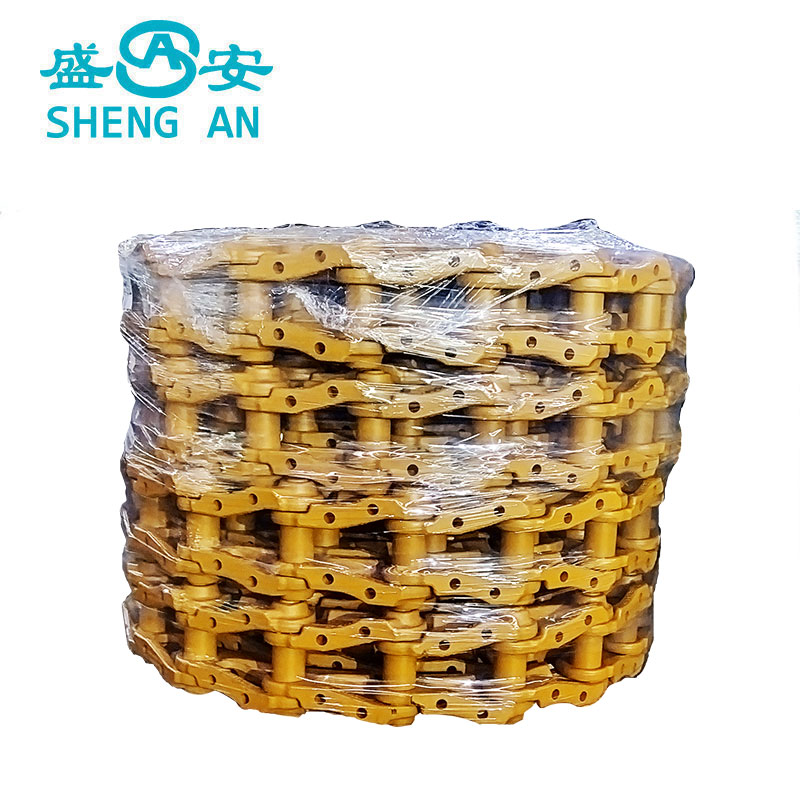

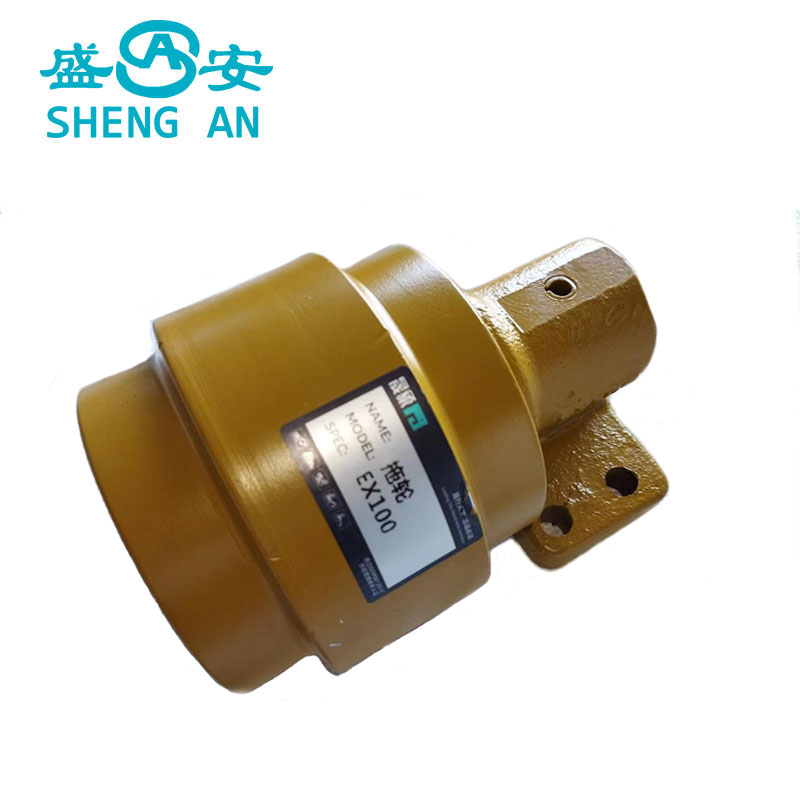

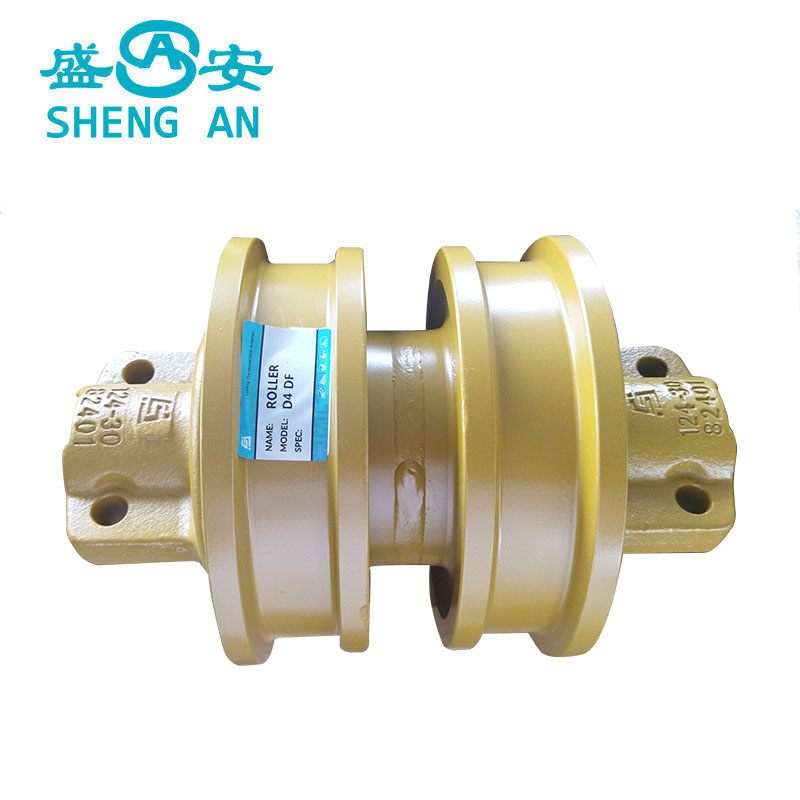

Excavator bottom rolleris a component of excavator or bulldozer that is located at the bottom of the machine and supports the weight of the track. Excavator bottom roller have double-row, sealed, and lubricated design that protects the shaft and bearing from debris and dust.

The tracks on excavators or bulldozers are made up of a series of interlocking metal plates, and the excavator bottom roller sit along the length of the track and support it as the machine moves. The basic structure of a Excavator bottom rollerconsists of an outer ring, an inner ring, a roller bearing, and a shaft. The outer ring is made of high-quality steel, and the surface is heat-treated for improved toughness and wear resistance. The inner ring is typically made of low-carbon alloy steel and heat-treated to wear-resistant properties. The roller bearing is designed to be sealed to ensure that foreign bodies will not enter, and multiple sealing components are added to ensure safe and long-term functionality.

Excavator bottom roller are critical components that support the weight of the excavator or bulldozer, reduce vibration, and improve the stability of the machine. excavator bottom roller directly affect the running speed, fuel consumption, and efficiency of the machine. As such, excavator bottom roller must be made of high-quality materials and designed for rugged application.

Product Parameter (Specification)

The following are the specifications and parameters of the excavator bottom roller:

|

Product name |

Excavator bottom roller |

|

Roller shell material |

50Mn/40Mn2 |

|

Color |

Black or yellow |

|

Surface of hardness |

|

|

Shaft material |

45#/40Cr |

|

Warranty period |

One year |

|

Case depth |

5-10mm |

|

Delivery period |

30day/45-60day |

|

Using time |

1000hour |

The following are some of the common characteristics and features of excavator bottom roller:High wear resistance: excavator bottom roller are exposed to harsh environments and need to withstand the wear and tear caused by heavy loads, uneven terrain, and debris. These components are typically made of high-quality steel and undergo heat treatment to improve their durability and wear resistance.

Effective sealing: excavator bottom roller are designed to be sealed tightly to prevent dust, dirt, and debris from entering into the bearing. Seals are placed on each end of the roller to eliminate any gaps.

Lubrication: excavator bottom roller require regular lubrication to ensure the smooth movement of the machine. Lubrication holes are usually added to the rollers to make the lubrication process easier.

Low noise: The bearings of the excavator bottom roller have a special design that helps to reduce noise during operation.

Easy installation: excavator bottom roller have a simple structure and are easy to install and maintain. They can be removed and replaced without dismantling the entire track assembly.Compatibility: excavator bottom roller are designed to fit specific models of excavators or bulldozers. These components should be chosen carefully to ensure compatibility with the machine.

Part number

Excavator bottom roller come in various types and specifications.

|

PC40 |

EX30 |

SK60-5 |

E70B |

DH55 |

SH60 |

MS110-5 |

D20-3 |

D4B |

|

PC60-5 |

EX55 |

SK75 |

CAT307 |

DH80 |

SH120 |

MS180 |

D20-6 |

D4C |

|

PC60-7 |

EX60-1 |

SK100 |

E305.5 |

DH150 |

SH200 |

MS070 |

D31-12 |

D3K |

|

PC75 |

EX60-2 |

SK120-3 |

E120B |

DH220 |

SH280 |

VIO55 |

D50 |

D4 |

|

PC100-5 |

EX60-3 |

SK200-3 |

E312 |

DH280 |

SH265 |

VIO75 |

D60 |

D4D |

|

PC200-5 |

EX70 |

SK200-5 |

E200B |

DH290 |

SH300 |

JS200 |

D65-12 |

D4H |

|

PC200-6 |

EX60-5 |

SK230 |

E320 |

DH300 |

SH350 |

JS220 |

D85E |

D5B |

|

PC200-7 |

EX120 |

SK200-6 |

E325 |

R80-7 |

HD250 |

LG60 |

D85 |

D5C |

|

PC200-8 |

EX200-1 |

SK300 |

E330 |

R130 |

HD450 |

LG906 |

D155 |

D5H |

|

PC300-3 |

EX200-2 |

SK140 |

E345 |

R200 |

HD700 |

U161 |

D355 |

D5 |

|

PC300-5 |

EX200-3 |

EC55 |

ZX55 |

R290 |

HD800-7 |

IHI50 |

D51EX |

D6D |

|

PC300-6 |

EX200-5 |

MX55 |

ZAX70 |

R305 |

HD1430 |

DX290 |

D61EX |

D6C |

|

PC300-7 |

EX300-1 |

EC140 |

ZAX200 |

R360-7 |

DX225-7 |

BD2G |

D65EX-12 |

D6R |

|

PC360 |

EX300-2 |

EC210 |

ZAX240-3 |

R450 |

DX300 |

D3 |

D155AX-5 |

D6H |

|

PC300-8 |

EX300-3 |

EC240 |

ZAX200-5G |

R912 |

DX340 |

D10N |

D275AX |

D7G |

|

PC400-7 |

EX300-5 |

EC290 |

ZAX270 |

YC35 |

DX150 |

D11N |

D3C |

D8K |

|

PC400-5 |

EX400-5 |

EC360 |

ZAX330-3 |

YC85 |

DX280 |

D931 |

BD2G |

D8N |

|

D3 |

D9N |

D3C |

D10N |

D3B |

D11N |

D933 |

D931 |

D9N |

|

D3B |

D933 |

|

|

|

|

|

|

|

Inventory

Sheng'an Machinery has rich experience in the production of excavator bottom roller and sufficient inventory.