- English

- 简体中文

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

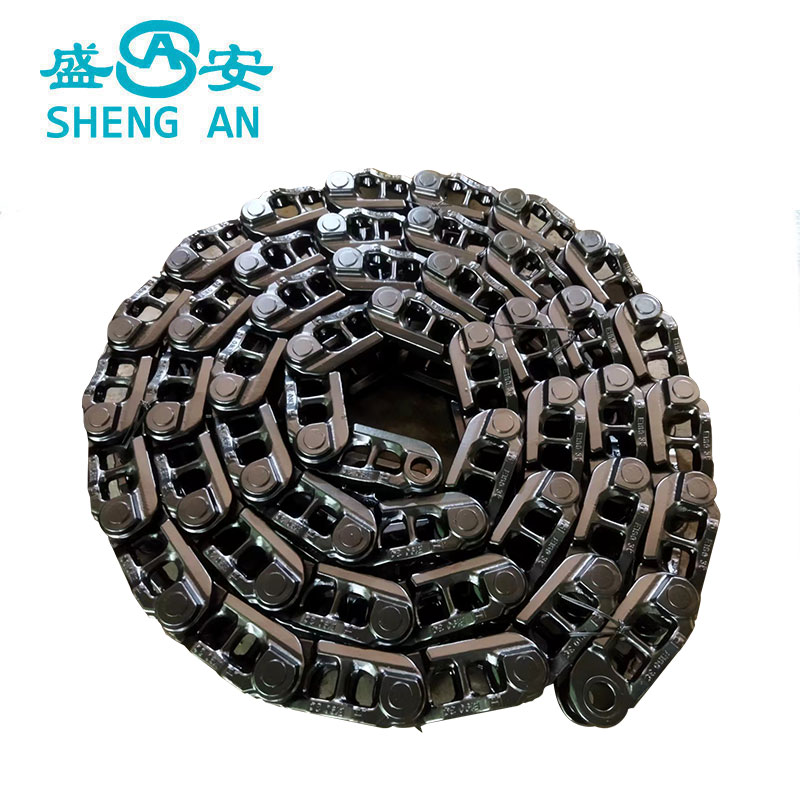

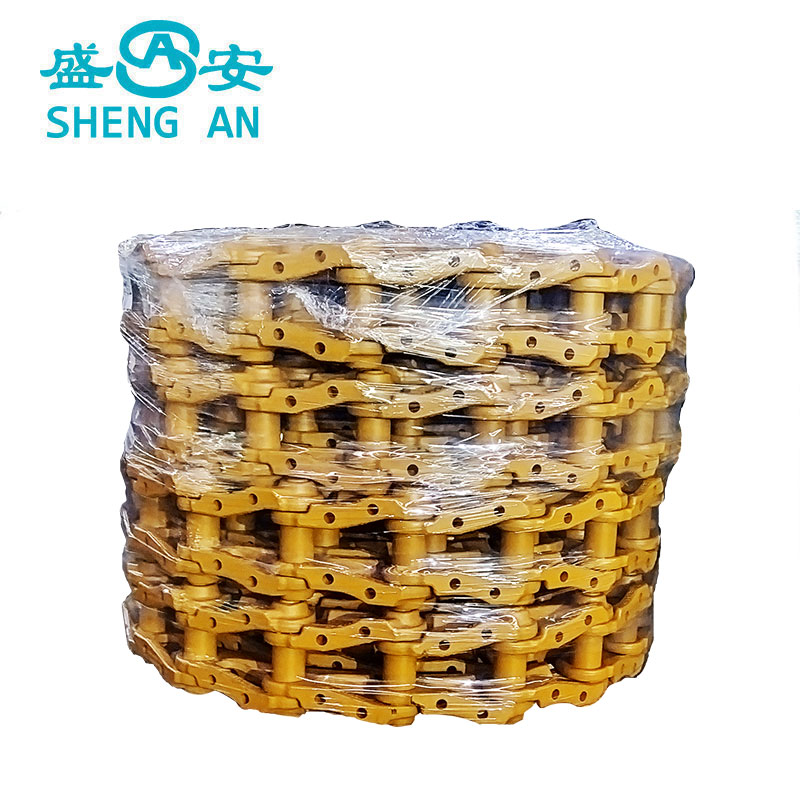

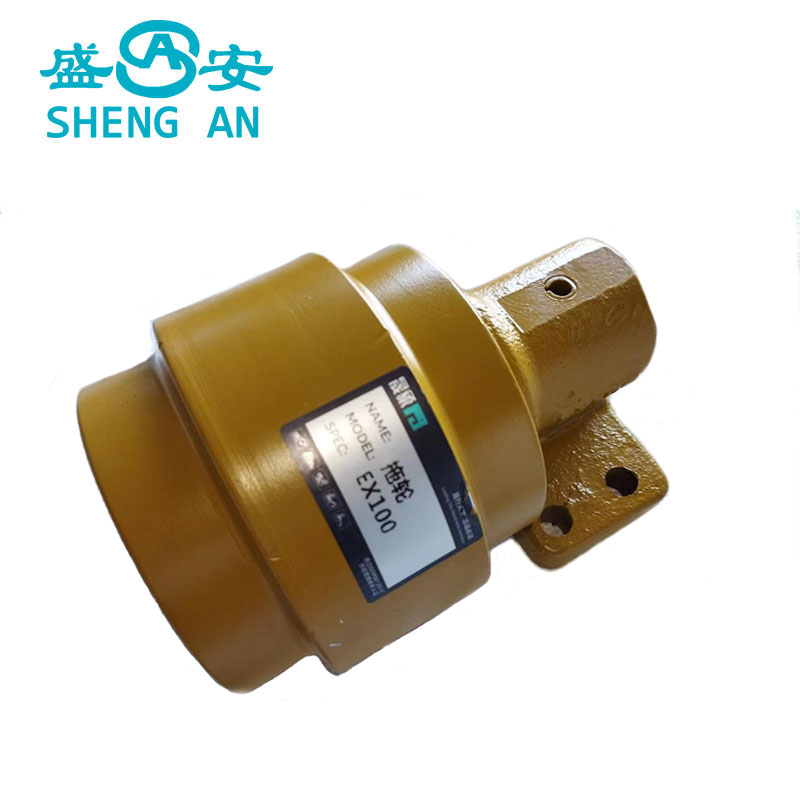

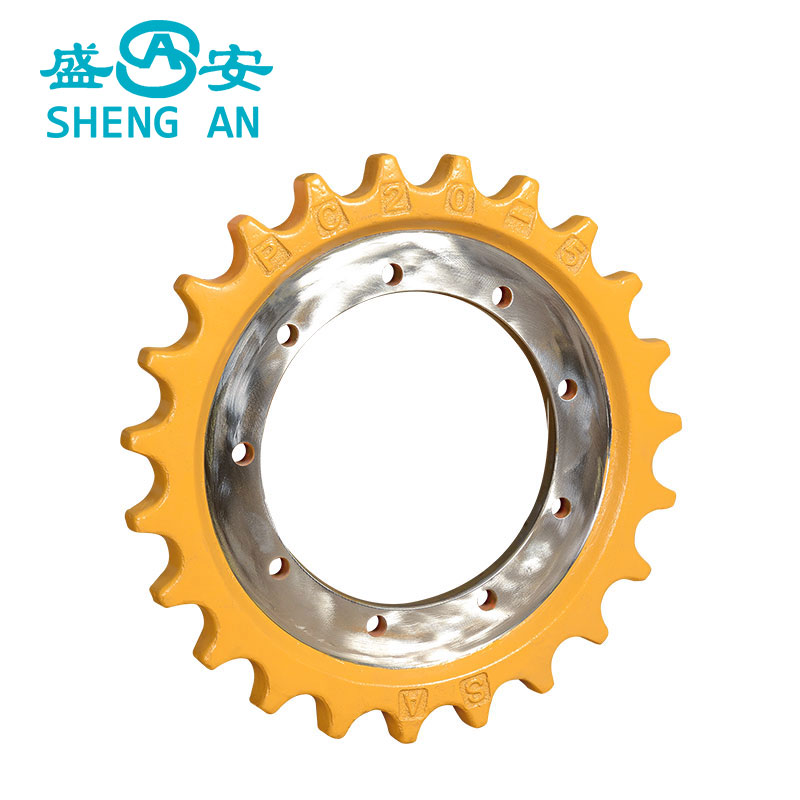

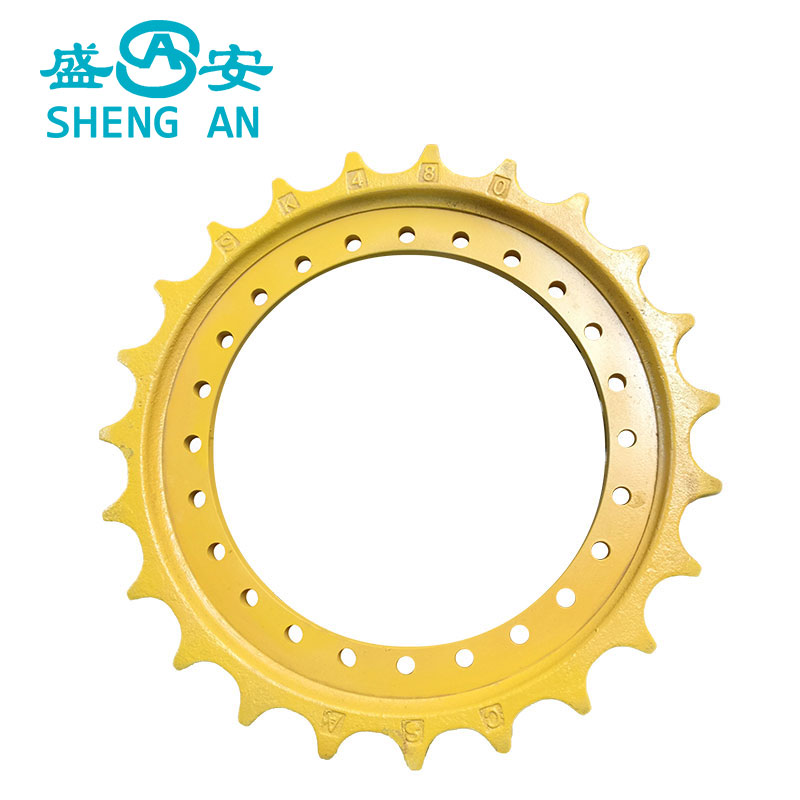

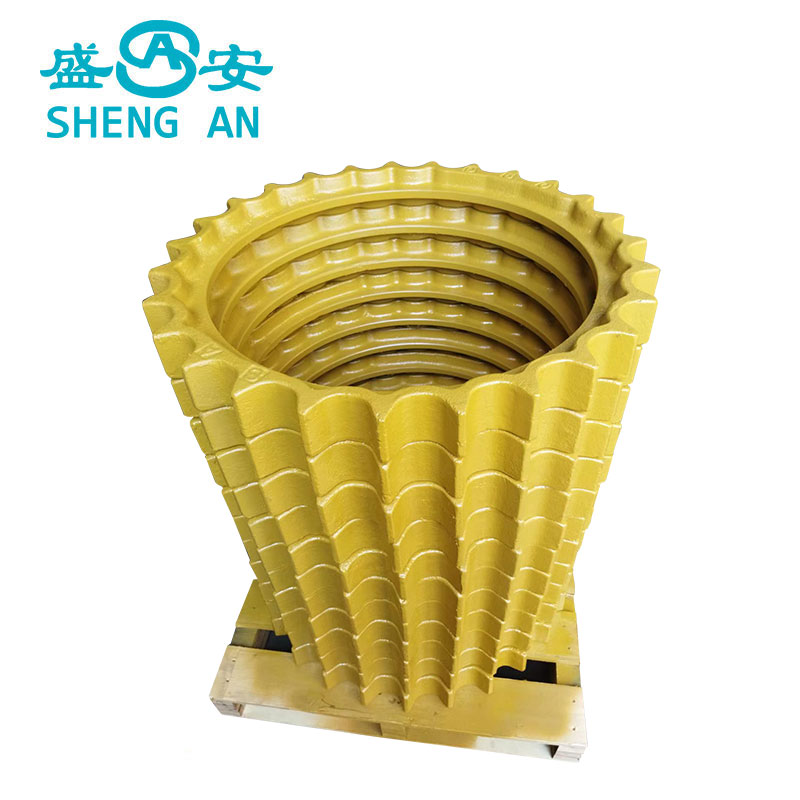

Excavator Track Sprocket

Fujian Sheng'an Machinery Development Co., Ltd. was established in 1985 and is a professional enterprise engaged in the research and development, manufacturing, and sales of excavator components. The company is located in Quanzhou City, Fujian Province, China. It has a modern production workshop and complete testing equipment. Its products cover key components of excavators such as track sprocket, track roller, carrier roller, bucket, Excavator Track Sprocket,idler and chains. The quality is stable and reliable, and it is highly trusted and praised by domestic and foreign customers.

Send Inquiry

Shengan Machinery Company's products have passed the ISO9001 quality management system certification and possess multiple patented technologies, with superior product performance and advanced technology. The company adheres to the principle of "creating reputation through quality and seeking development through technology", and always maintains a high level of attention and pursuit for quality and technology. The company's sales network in domestic and international markets has covered multiple countries and regions such as China, the United States, Japan, Europe, the Middle East, and Southeast Asia.

At present, Quanzhou Sheng'an Machinery Development Co., Ltd. in Fujian Province has become one of the leading enterprises in China's excavator parts industry, continuously expanding its product line and market, and providing high-quality excavator parts and services to global customers.

The excavator track sprocket of an excavator generally refer to the gears on the driving wheels of the excavator. The sprocket is an important component of an excavator, which is connected to the track and generates power to drive the excavator's movement and operation.

Excavator track sprocket are generally made of high-strength alloy steel materials, which undergo heat treatment and quenching to improve their hardness and wear resistance, thereby extending their service life. The size and shape of the sprocket vary depending on the excavator model and usage conditions.

The main purpose of excavator track sprocket is to transfer the power output to the tracks, thereby driving the entire excavator to travel and operate. Specifically, the main uses of excavator sprocket are as follows:

Driving and turning of excavators: The sprocket of excavators transmit power to the tracks, helping excavators travel and turn in different terrains and working conditions, making the machine more flexible and efficient.

The climbing ability of excavators: The design of the sprocket of excavators can provide strong load-bearing capacity and grip, allowing excavators to have better climbing and obstacle passing abilities.

The operational capability of excavators: The operation of the sprocket of excavators can provide stable driving and operational support for excavators, thereby better completing various tasks such as excavation, shoveling, and handling.

Improving the maneuverability of excavators: The design of excavator track sprocket also focuses on improving the machine's maneuverability and stability, making driving operations more convenient and safe.

In summary, the main purpose of excavator track sprocket is to provide powerful power support and stability assurance for excavators, allowing machines to efficiently travel and operate in complex terrains and working conditions.

Excavator Track Sprocket Product Parameter (Specification)

|

Product name |

Sprocket |

|

Material |

|

|

Color |

Black or Yellow |

|

Surface hardness |

|

|

5-10mm |

|

|

Warranty |

One year |

|

Production Process |

casting |

Excavator track sprocket have the following characteristics:

High hardness: excavator track sprocket are usually made of high-strength alloy steel that has undergone heat treatment and quenching. High hardness, strong wear resistance, and long service life.

Strong load-bearing capacity: The track sprocket of the excavator can withstand large loads, helping the excavator to travel under different road conditions.

Good wear resistance: These excavator sprocket are usually made of materials with good wear resistance and durability to prevent wear caused by frequent driving.

Strong body stability: The design of excavator sprocket can improve the stability of the body, prevent tilting during driving, and improve the handling of the excavator.

Easy to install: The installation of the sprocket is relatively simple. It can be replaced by replacing aged or damaged sprockets to reduce maintenance costs.

Overall, the design of excavator track sprocket emphasizes strong load-bearing capacity, durability, vehicle stability, and comfort, and can provide excellent performance under different working conditions.

Excavator Track Sprocket Part number

The following are the track sprocket models we produce.

|

PC20 |

EX30 |

SK035 |

R60 |

EC55 |

SH120 |

SY65 |

|

PC20-6 |

EX55 |

SK040 |

R80 |

EC60 |

SH200 |

SY215 |

|

PC20-5 |

EX55 |

SK60-8 |

R130 |

EC150 |

SH260 |

SY215 |

|

PC30 |

EX60-1 |

SK045 |

R135 |

EC140 |

SH280 |

SY235 |

|

PC40 |

EX60-2 |

SK60 |

R140 |

EC210 |

SH300 |

SY335B |

|

PC40-3 |

EX70 |

SK100 |

R150 |

EC240 |

SH340 |

SY365A |

|

PC56 |

EX100 |

SK140 |

R200 |

EC290 |

SH580 |

SY365 |

|

PC50 |

EX150-1 |

SK170 |

R210 |

EC360 |

SH350 |

SY385 |

|

PC40-7 |

EX200-1 |

SK200-3 |

R285 |

EC460 |

SH350 |

SY465 |

|

PC60-5 |

EX200-2 |

SK200-8 |

R290 |

EC480 |

HD250 |

DX55 |

|

PC60-6 |

EX200-3 |

SK210 |

R305 |

EC480D |

HD400 |

DX300 |

|

PC60-7 |

EX200-5 |

SK220 |

R360 |

DH55 |

HD450 |

DX225 |

|

PC71 |

EX300-1 |

SK230 |

R455 |

DH130 |

HD700 |

DX500 |

|

PC75 |

EX300-3 |

SK250-8 |

E70B |

DH150 |

HD820 |

JS80 |

|

PC78 |

EX300-5 |

SK07-2 |

E312 |

DH220 |

HD1250 |

JS130 |

|

PC90 |

EX360 |

SKO7N2 |

E120B |

DH220 |

HD1430 |

JS140 |

|

PC100-3 |

EX400 |

SK09 |

E200B |

DH258 |

UH025 |

JS200 |

|

PC100-5 |

EX500 |

SK300 |

E300B |

DH280 |

UH04-7 |

JS220 |

|

PC120-6 |

ZAX60 |

SK330 |

E215 |

DH300 |

UH045-5 |

SWE50 |

|

PC200-3 |

ZAX200-3 |

SK330-8 |

E320 |

DH370 |

UH045-7 |

SWE65 |

|

PC200-5 |

ZAX200-5 |

SK350 |

E325 |

DH450 |

UH063 |

SWE70 |

|

PC300-5 |

ZAX240 |

SK035SR |

E315 |

DH500 |

UH07-5 |

SWE85 |

|

PC300-6 |

ZAX330-8 |

SK400 |

E330 |

YC35 |

UH084 |

MS110-5 |

|

PC360-8 |

ZAX270 |

SK450 |

E345 |

YC60 |

UH07-7 |

MS180 |

|

PC400-5 |

ZAX650 |

SK480 |

E305.5 |

YC85 |

UH083 |

TB175 |

|

PC400-6 |

QYY TK40 |

LS2800 |

IHI80 |

K907-2 |

JBT85 |

|

|

PC800 |

QYY TK60 |

CX210 |

FR60 |

柳工936 |

|

|

|

PC1250-7 |

LS2600 |

SC360 |

LG906 |

K91-3 |

|

|

Excavator Track Sprocket Inventory

We have a rich variety and sufficient inventory.